Fiddy + Coyote = Patman

#61

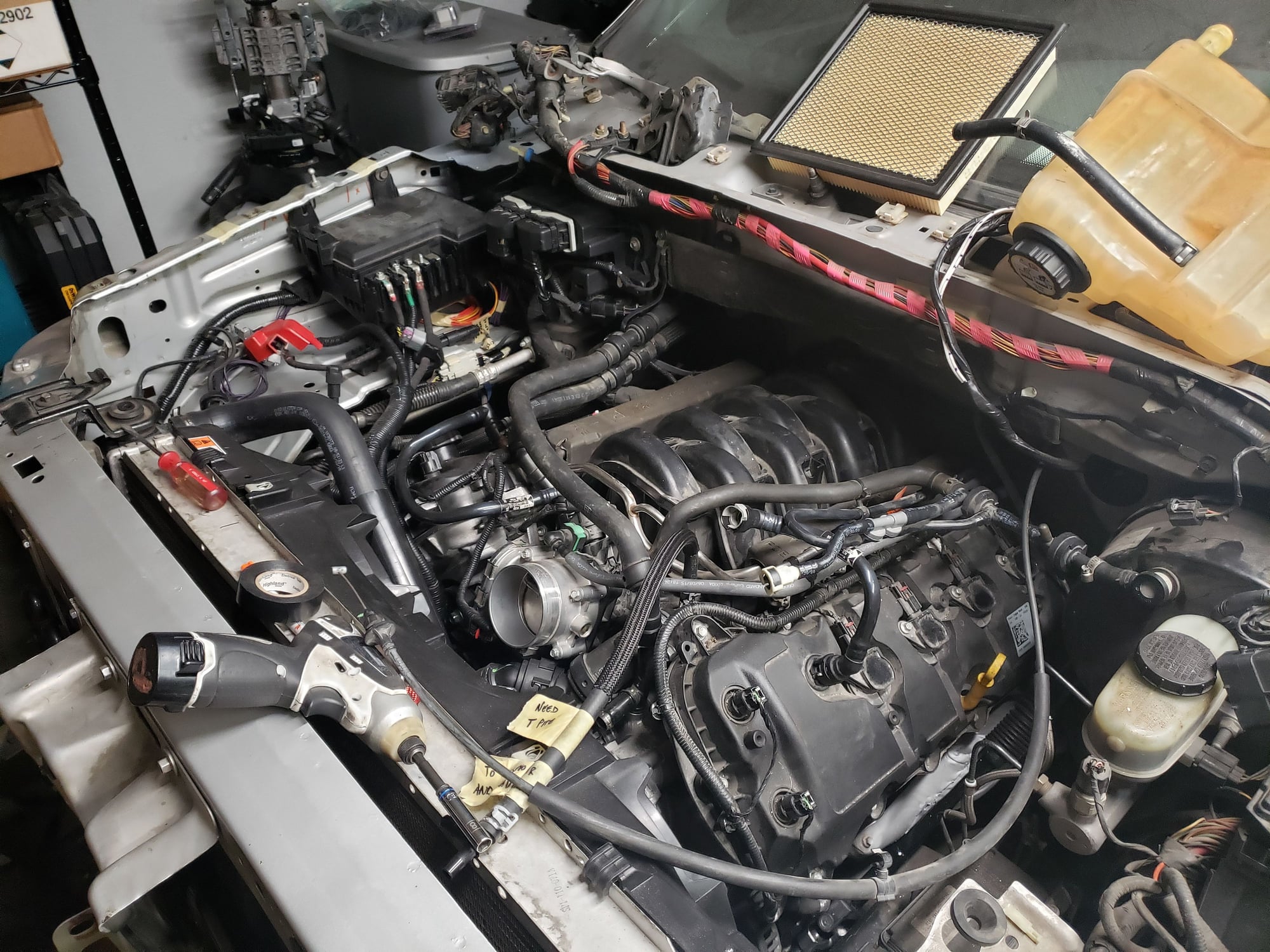

Test fitting the BJB on the RH apron area

Using an existing hole on the upper rail, will add a threaded insert for the other mounting point

*not pictured* I also ran the engine bay harness across under the radiator, got it safely routed and secured to the fan shroud. Got the fans plugged in.

I now have a 2003 with FACTORY ELECTRIC FANS!!!

its really starting to look like a complete engine bay!

Next up: Frame rail harness, gonna thin this one out a bit. Shouldnt take very long.

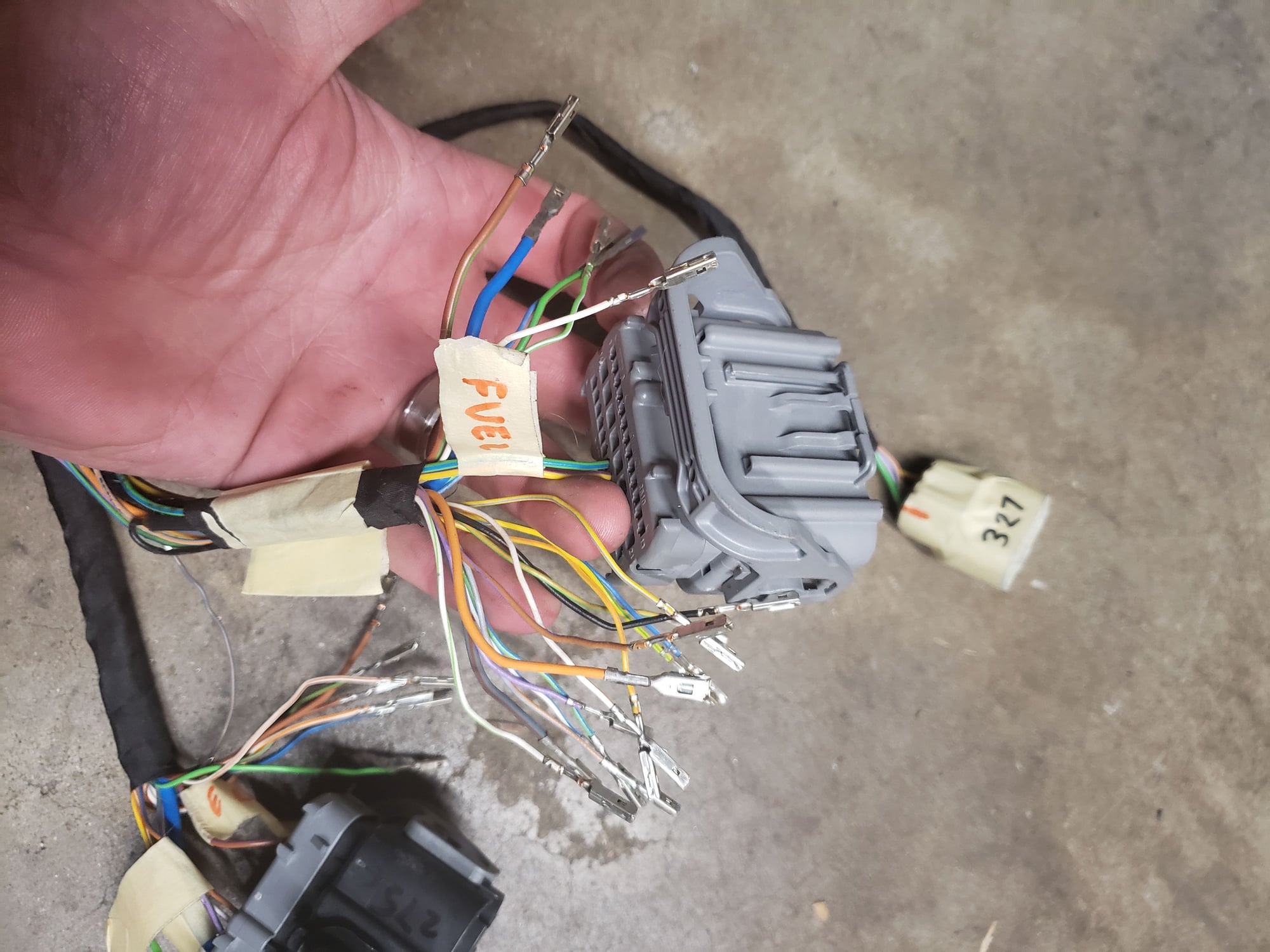

Took me about 30 minutes to identify and label all the connectors on this harness

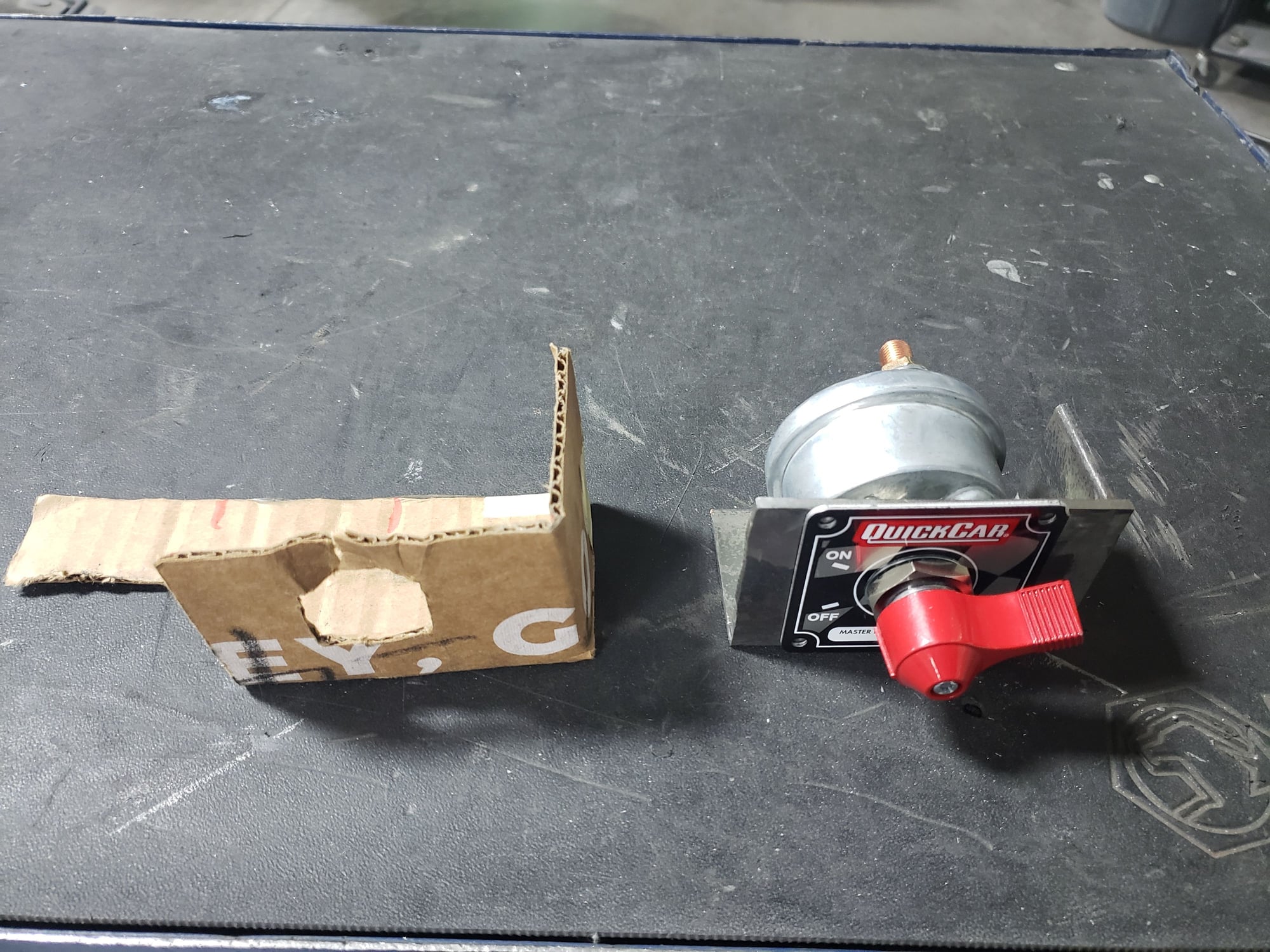

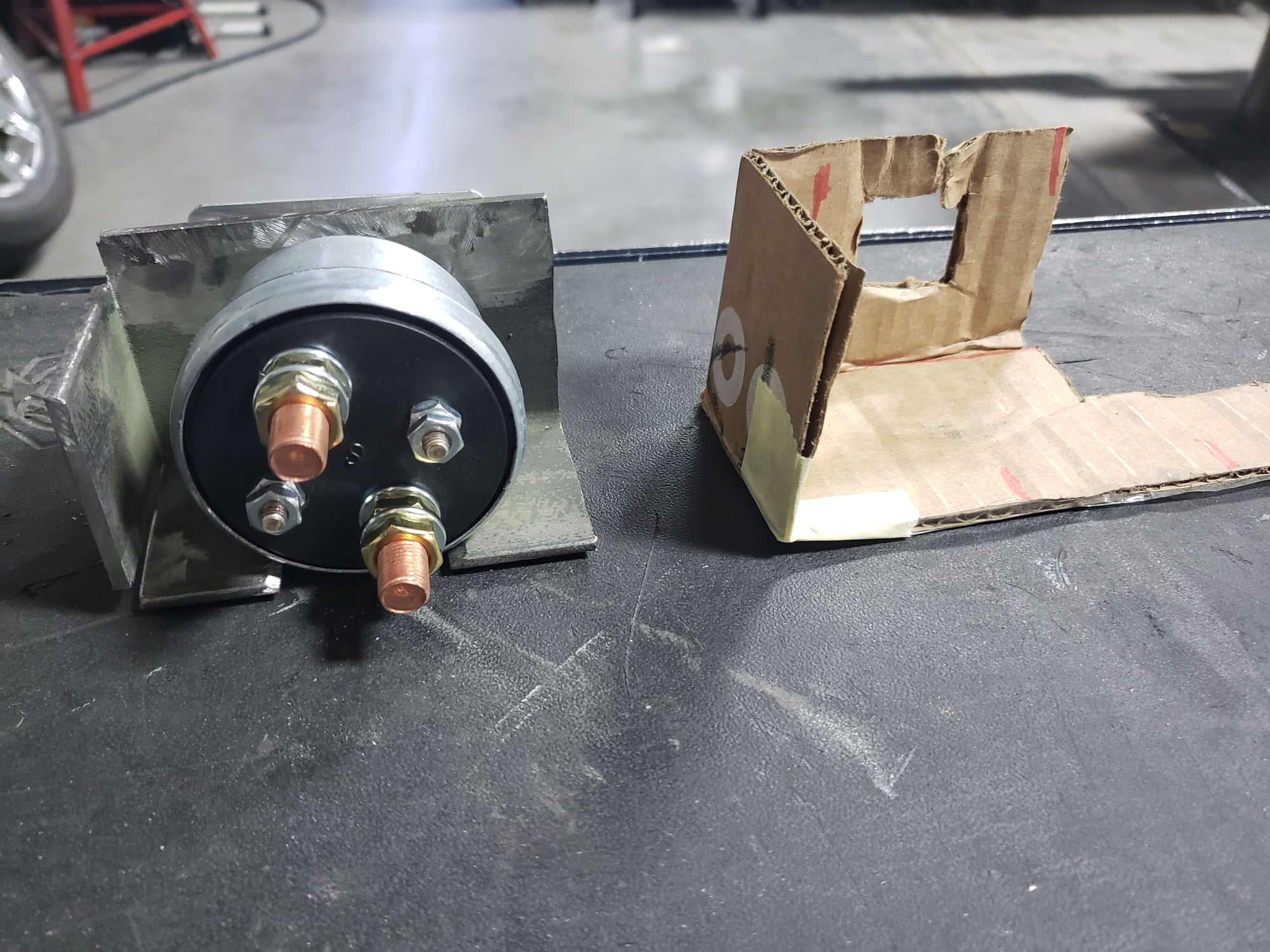

sneak peek of another side project that I've got in progress

As of Monday night I've personally invested 190 hours in the project now!!!

I haven't totaled up the work other people have put in, I'd guess somewhere around 20-25 hours of additional friend help/work

Thats all for now. I'll try and stay motivated and keep on rocking through this project.

#63

Wow Patman, thanks for documenting this whole thing. I'm just about to pull the trigger on a coyote/6R80 4x4 setup for my 2001 Reg cab. Been trying to ditch the thirsty 5.4 for a long time now!

Just a few questions and thoughts...

It looks like the frame/subframe differences between a 2x4 and a 4x4 truck would allow me to skip the Moroso oil pan.

Did the stock mounts bolt up or did they require some modification? In the pics it looks like you reused the 4.6 mounts?

I was wondering if the alternator would collide with the steering box or shaft, did you get a sense of that before you removed it in favor of the EPAS?

In all of my research, I recall reading somewhere the importance of using minimum 12AN fittings and hoses for remote oil filter setups. I can't remember exactly where I saw it but I'm almost positive it was a Ford Racing document. Just food for thought!

Thanks again for sharing your work complete with photos. A great contribution to the forum! Actually found your project on the FB group, followed it here.

Just a few questions and thoughts...

It looks like the frame/subframe differences between a 2x4 and a 4x4 truck would allow me to skip the Moroso oil pan.

Did the stock mounts bolt up or did they require some modification? In the pics it looks like you reused the 4.6 mounts?

I was wondering if the alternator would collide with the steering box or shaft, did you get a sense of that before you removed it in favor of the EPAS?

In all of my research, I recall reading somewhere the importance of using minimum 12AN fittings and hoses for remote oil filter setups. I can't remember exactly where I saw it but I'm almost positive it was a Ford Racing document. Just food for thought!

Thanks again for sharing your work complete with photos. A great contribution to the forum! Actually found your project on the FB group, followed it here.

#64

I believe most people put the PS pump back on in the lower left corner and move the alternator up top with an aftermarket bracket.

Thanks for stopping by and keeping me encouraged to keep moving

#65

#66

Thanks for the info. I'll surely be following along as you beat down the tall grass. Wish I was of more help, although you don't look like you need it.

Believe it or not I actually had a 2.7 EB motor sitting in this frame before I learned it had a cracked block. Luckily I saw it, reversed course and drove the 5.4 out of there not more than 6 hours later. Removed the cab for that one too. Thinking the 5.0 will be a hoot in this truck.

Believe it or not I actually had a 2.7 EB motor sitting in this frame before I learned it had a cracked block. Luckily I saw it, reversed course and drove the 5.4 out of there not more than 6 hours later. Removed the cab for that one too. Thinking the 5.0 will be a hoot in this truck.

#69

#70

#71

#72

#73

#74

#75

Cutting the factory battery/starter cable

Crimping a ring terminal onto the 2015 starter cable

Did the same thing with the main ground cable. I will ground the other end on the frame

Pulled the back seat out to route the battery cable through the cab

Also installed my coil covers from my 2014 . Nice little eye candy to keep me motivated to finish off the beast of the wiring job

Last edited by Patman; 03-25-2019 at 12:04 AM.