Question for Trany Expert and / or Ford Tech (OSS ratios between 1997 and 2003)

#1

I hope someone can help me here. Let me explain my situation.

I replaced the 4R70W transmission in my 1997 F-150 4x4 with a 2003 4R70W. (The harness connections were changed to work with the 2003 and it is running on the 1997 PCM)

Afterwards I discovered that the transmissions OSS differ, I.E. they have a different pulse rate at the same speed. The 2003 is significantly higher.

If I run with the OSS connected no faults codes are thrown, but the transmission won't let me get above 15 or 20 MPH. Disconnecting the OSS allows the truck to run at what seems to be normal, but I have a permanently illuminated SEL on my dash, for no OSS signal.

I had a shop look at it and after they hooked it up to their computers and charged me $300 they told me the OSS signal was way to high and that that must be the reason the PCM wasn't controlling the shifting correctly.

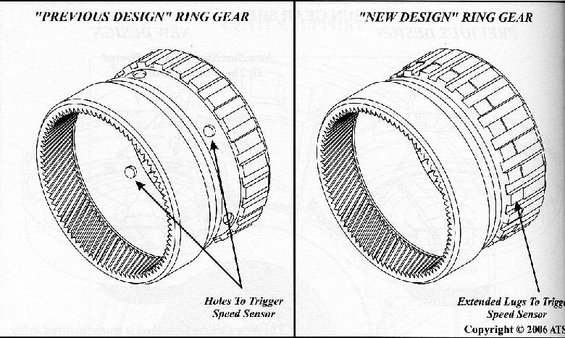

So apparently between 1997 and 2003 there was a change in the OSS tone ring and sensor that gives it a higher pulse rate at a given speed.

Can anyone tell me one or both of the following.

I've a devise that can modify the pulse rate, but I need to be able to figure out the ratio of the difference to make it work.

Thank you for any help that anyone can offer.

Doug

I replaced the 4R70W transmission in my 1997 F-150 4x4 with a 2003 4R70W. (The harness connections were changed to work with the 2003 and it is running on the 1997 PCM)

Afterwards I discovered that the transmissions OSS differ, I.E. they have a different pulse rate at the same speed. The 2003 is significantly higher.

If I run with the OSS connected no faults codes are thrown, but the transmission won't let me get above 15 or 20 MPH. Disconnecting the OSS allows the truck to run at what seems to be normal, but I have a permanently illuminated SEL on my dash, for no OSS signal.

I had a shop look at it and after they hooked it up to their computers and charged me $300 they told me the OSS signal was way to high and that that must be the reason the PCM wasn't controlling the shifting correctly.

So apparently between 1997 and 2003 there was a change in the OSS tone ring and sensor that gives it a higher pulse rate at a given speed.

Can anyone tell me one or both of the following.

- How many "teeth" are on the 1997 and 2003 OSS tone ring?

- Is there a certain pulse rate for a given speed that is expected from the OSS on the 1997 and 2003?

I've a devise that can modify the pulse rate, but I need to be able to figure out the ratio of the difference to make it work.

Thank you for any help that anyone can offer.

Doug

#2

#3

#4

#5

Darrin you ROCK

I've just left the sensor unplugged and it shifts fine based on the PCM default programing, but you have a constant Engine Warning Light on because of it.

I have found a devise that will adjust the signal, I just didn't know what I was adjusting.

The device is manufactured by Dakota Digital. It's the

Universal Speedometer Signal Interface SGI-5 http://www.dakotadigital.com/index.c...rod/prd126.htm

Now knowing that the signal difference is I should be able to figure out the settings.

I've emailed Dakota Digital Tech Support for some assistance in figuring out the setting for the device. I will post thier answer here once I have it.

Last edited by DDan1967; 03-17-2010 at 02:18 AM. Reason: Additional information

#6

DDan1967,

Glad I could point you back to your old post to help you out. I can’t believe you were living with this shift issue. I have driven my truck for a few days and I am already about to pull my hair out.

That Dakota box looks like it will work but it will be my second option.

I was using my SCT flash tuner to log my truck yesterday and found that it logs just about every transmission sensor, but the oss since it’s not plugged in. So now I just need the correct sensor for the transmission, in my case a sensor for a 07, s I can log and divide the signal by 25% (Stock was 6 pulses per driveshaft revolution and now it’s 24 and causing the issue) With the signal divided the PCM should say "hey you’re not going 200+mph" at 15mph. LOL

I will also be speaking with SCT again today to see if the code in the PCM can be changed now that I have my computer strategy to give them. (It’s a software version so they know what field the code is in.) The only issues is that IF this works I will need to buy a dedicated SCT X3 programmer for my truck since the one I logged with is for my mustang and its married to that car so it can’t be used to program another vehicle.

I just found this on the net and thought it might help us figure out how to setup a device like the Dakota digital device.

Finding driveshaft revolutions per mile.

"The first thing to know is how many revolutions the tires make in one mile. To calculate this, measure the diameter of your tires. 26" is about average for F60-15's or 245-60-15's. Multiply this measurement (26") by pi (3.1416). This will give you the circumference of the tire. Next, divide one mile in inches (63360) by the circumference of tire (63360 divided by (26 x pi)=776). This equals the revs per mile of the tire. Now multiply this number by the rear axle ratio to give you the number of drive shaft revs per mile (776 x 3.91= 3033)."

Glad I could point you back to your old post to help you out. I can’t believe you were living with this shift issue. I have driven my truck for a few days and I am already about to pull my hair out.

That Dakota box looks like it will work but it will be my second option.

I was using my SCT flash tuner to log my truck yesterday and found that it logs just about every transmission sensor, but the oss since it’s not plugged in. So now I just need the correct sensor for the transmission, in my case a sensor for a 07, s I can log and divide the signal by 25% (Stock was 6 pulses per driveshaft revolution and now it’s 24 and causing the issue) With the signal divided the PCM should say "hey you’re not going 200+mph" at 15mph. LOL

I will also be speaking with SCT again today to see if the code in the PCM can be changed now that I have my computer strategy to give them. (It’s a software version so they know what field the code is in.) The only issues is that IF this works I will need to buy a dedicated SCT X3 programmer for my truck since the one I logged with is for my mustang and its married to that car so it can’t be used to program another vehicle.

I just found this on the net and thought it might help us figure out how to setup a device like the Dakota digital device.

Finding driveshaft revolutions per mile.

"The first thing to know is how many revolutions the tires make in one mile. To calculate this, measure the diameter of your tires. 26" is about average for F60-15's or 245-60-15's. Multiply this measurement (26") by pi (3.1416). This will give you the circumference of the tire. Next, divide one mile in inches (63360) by the circumference of tire (63360 divided by (26 x pi)=776). This equals the revs per mile of the tire. Now multiply this number by the rear axle ratio to give you the number of drive shaft revs per mile (776 x 3.91= 3033)."

Last edited by RuthlessSVT; 03-17-2010 at 08:54 AM.

#7

I got the reply from Dakota Digital Technical Support. Talk about being fast and helpful. I don't think I've ever had an email to a company returned so quickly.

GO DAKOTA DIGITAL

Anyway this how they said to set up thier SGI-5

"An exact 4:1 ratio drop (24 to 6) would be the configuration of having switches 3 and 4 on and using OUT3 should be right on."

I already have the SGI-5 now I just have to get it installed.

GO DAKOTA DIGITAL

Anyway this how they said to set up thier SGI-5

"An exact 4:1 ratio drop (24 to 6) would be the configuration of having switches 3 and 4 on and using OUT3 should be right on."

I already have the SGI-5 now I just have to get it installed.

Last edited by DDan1967; 03-19-2010 at 01:35 PM. Reason: Corrected part number

Trending Topics

#8

^ Get that baby installed and get back to us!

Did you find the OSS wire at the PCM or are you running wires from outside of the truck?

I am on hold with SCT to see if we can tune this out of the PCM without an add on device. Depending on their answer I might be looking for that OSS wire in the cab to wire the Dakota up to.

I dont see a SGI-I listed only the SGI-5??

Did you find the OSS wire at the PCM or are you running wires from outside of the truck?

I am on hold with SCT to see if we can tune this out of the PCM without an add on device. Depending on their answer I might be looking for that OSS wire in the cab to wire the Dakota up to.

I dont see a SGI-I listed only the SGI-5??

Last edited by RuthlessSVT; 03-17-2010 at 03:19 PM.

#9

#10

I spoke to a shop yesterday and found out something that may help other people. The front sensor (input shaft speed) on the transmission, located on the same side as the OSS sensor and about mid trany, is a different sensor. This means they are not interchangable. (Nuts because they trany had one of those and not the OSS sensor) Since my trany was built in 07 I ordered a 07 OSS sensor and they found a connector that works with it.  The harness plug cost more than the sensor itself by $3. lol

The harness plug cost more than the sensor itself by $3. lol

I am still waiting to hear back from my SCT tuner so he can make the oss table correcting in the PCM. I still need to pickup SCT X3 programmer to load the tune onto the PCM and thats the most expensive part to this fix.

I still need to pickup SCT X3 programmer to load the tune onto the PCM and thats the most expensive part to this fix.

The harness plug cost more than the sensor itself by $3. lol

The harness plug cost more than the sensor itself by $3. lolI am still waiting to hear back from my SCT tuner so he can make the oss table correcting in the PCM.

I still need to pickup SCT X3 programmer to load the tune onto the PCM and thats the most expensive part to this fix.

I still need to pickup SCT X3 programmer to load the tune onto the PCM and thats the most expensive part to this fix.

#11

#12

I'm sorely tempted to caugh up the mula for that tuner. Troyer Performance offers it with 3 custom tunes.

Let me see, do I want to craw around and contort my body into unnatrual postions to just fix on thing. Or do I want to spend some cash, plug something in with little effort under the dash and fix the problem plus see performance gains.

Hmm

Let me see, do I want to craw around and contort my body into unnatrual postions to just fix on thing. Or do I want to spend some cash, plug something in with little effort under the dash and fix the problem plus see performance gains.

Hmm

Last edited by DDan1967; 03-19-2010 at 02:08 PM.

#14

My new OSS sensor is here along with the harness connector.  Now I just need my programmer and tune for the SCT X3.

Now I just need my programmer and tune for the SCT X3.

I am going to guess that the PCM is the + and the other side of the harness is -. Would anyone know if that is right before I start cutting wires. I wouldnt want to splice the connector in wrong and cost me more time.

For anyone following this the parts for the 07 4r70e is as follows...

OSS sensor: Ford Genuine Parts 6L3Z-7H103-AA

Wiring pigtail kit: Motorcraft WPT-159 1U2Z-14S411-BPA (Thats all the # on the package and it comes with heat shrink).

Now I just need my programmer and tune for the SCT X3.

Now I just need my programmer and tune for the SCT X3.I am going to guess that the PCM is the + and the other side of the harness is -. Would anyone know if that is right before I start cutting wires. I wouldnt want to splice the connector in wrong and cost me more time.

For anyone following this the parts for the 07 4r70e is as follows...

OSS sensor: Ford Genuine Parts 6L3Z-7H103-AA

Wiring pigtail kit: Motorcraft WPT-159 1U2Z-14S411-BPA (Thats all the # on the package and it comes with heat shrink).

#15

My truck is fixed!

I SCT logged the truck with the new OSS sensor on the factory tune and the readings were WAY high causing the truck to go straight into 4th gear. At least I knew my OSS sensor wiring was good and that was what I was testing.

After that test I loaded the custom SCT tune into the truck to correct the OSS sensor pulse rate and the 07 4r70e transmission shifts like a dream.

I want to thank everyone that has helped me with this. I couldn't have done it with out your help!

If anyone finds this post and needs help dont be afraid to get in touch with me. I can even point you to the guy that made my SCT tune.

I SCT logged the truck with the new OSS sensor on the factory tune and the readings were WAY high causing the truck to go straight into 4th gear. At least I knew my OSS sensor wiring was good and that was what I was testing.

After that test I loaded the custom SCT tune into the truck to correct the OSS sensor pulse rate and the 07 4r70e transmission shifts like a dream.

I want to thank everyone that has helped me with this. I couldn't have done it with out your help!

If anyone finds this post and needs help dont be afraid to get in touch with me. I can even point you to the guy that made my SCT tune.