5.4 3V Build.

#1

5.4 3V Build.

Decided to build a 5.4 3V motor. Forged bottom end. 'Head Job' Etc etc etc.

Anyhow I managed to find an 09 long block for under a grand.

Block:

Heads:

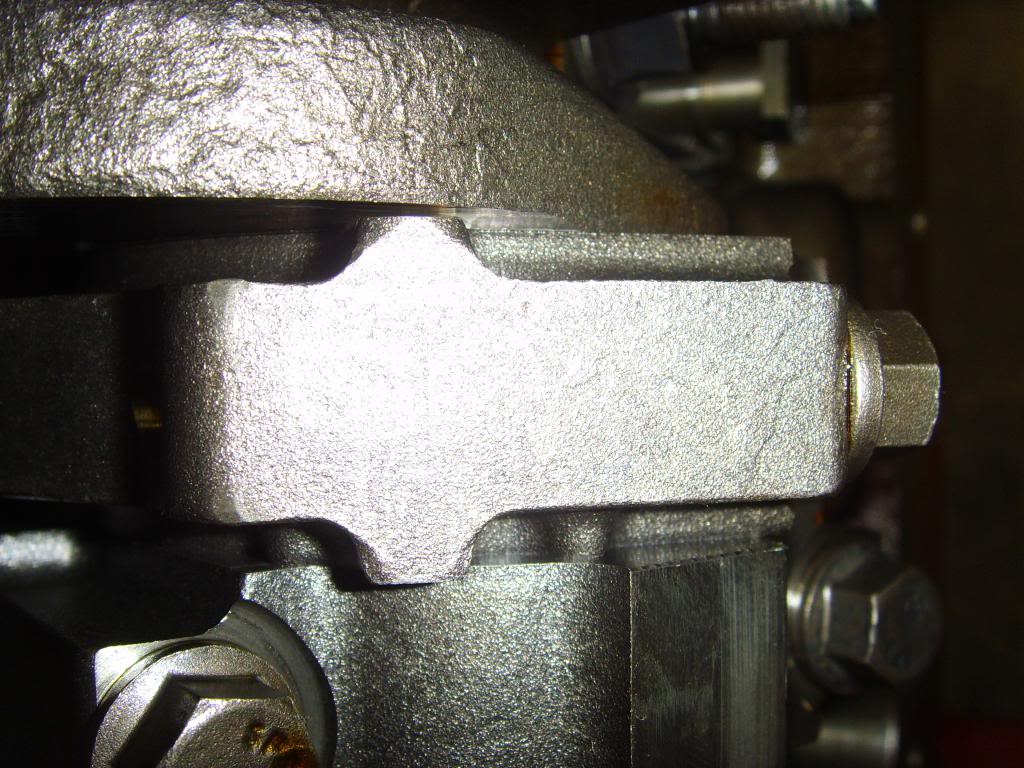

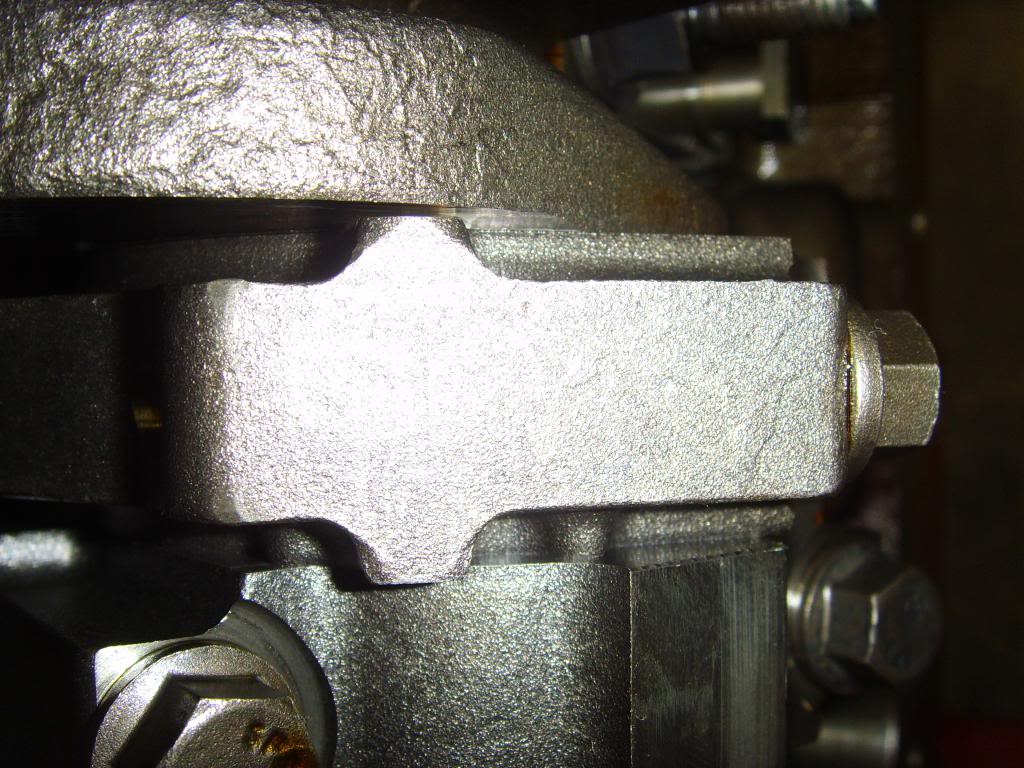

Started to strip: Cold crack Big end caps.

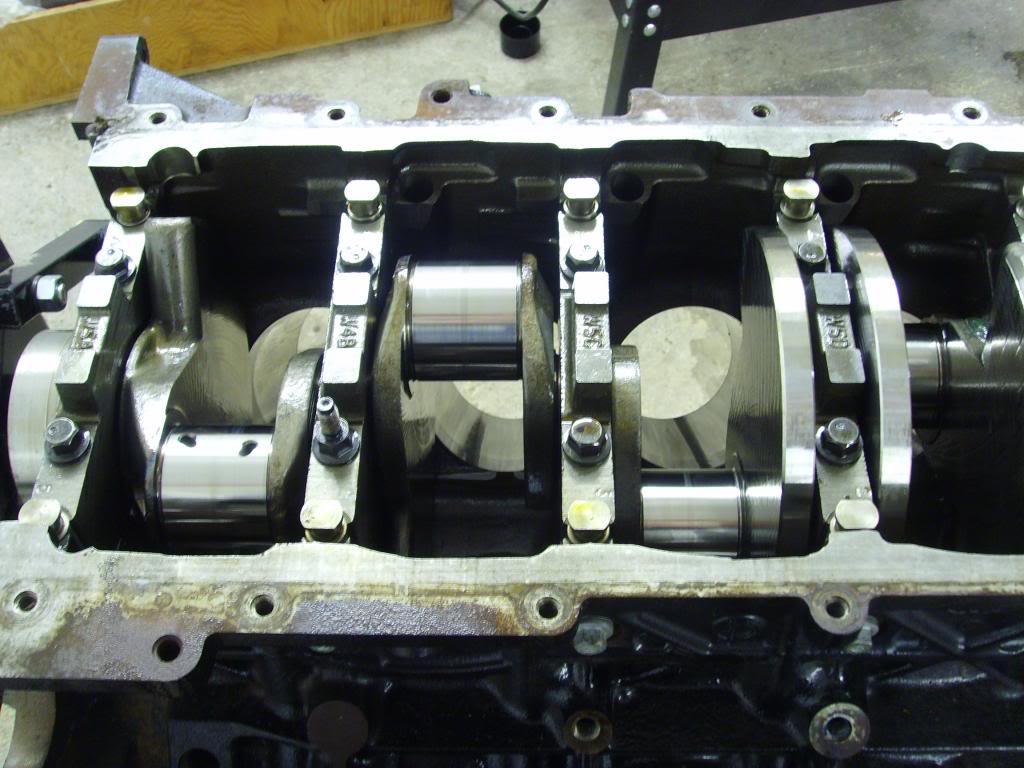

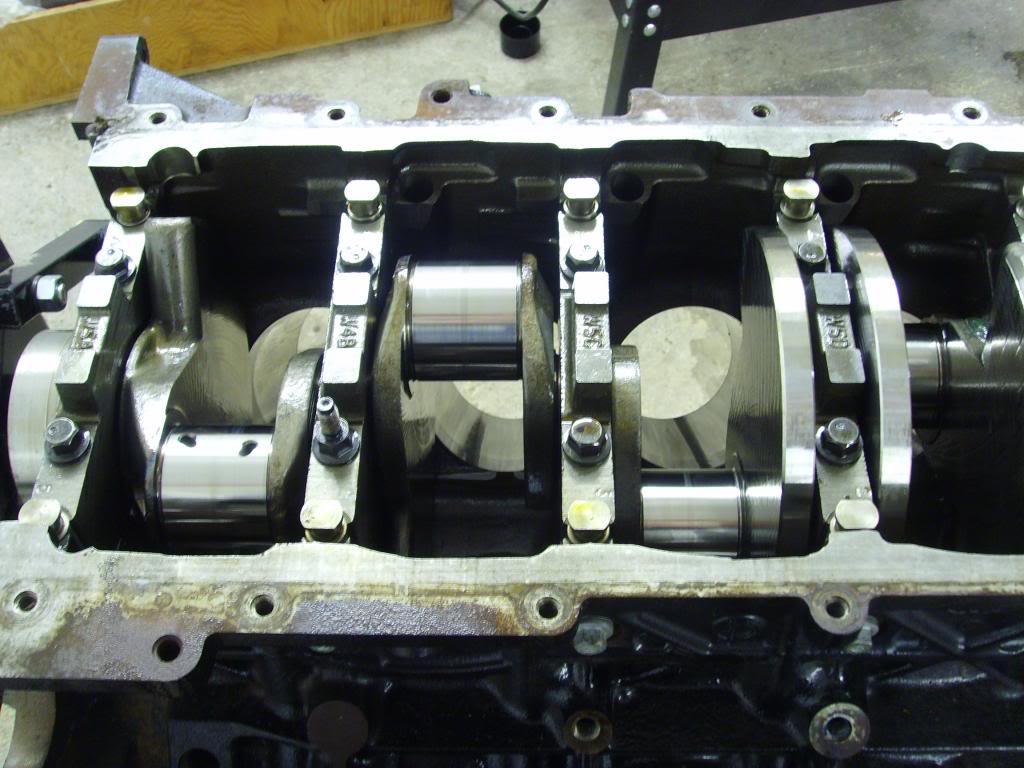

Pistons: Big ends are just like brand new.

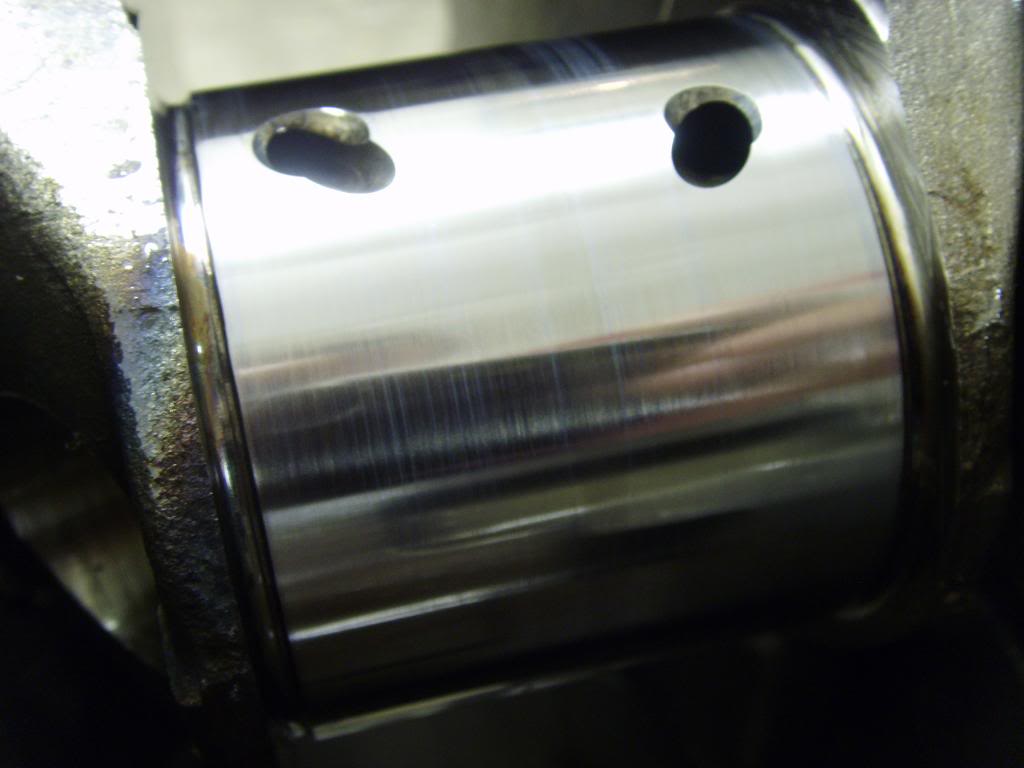

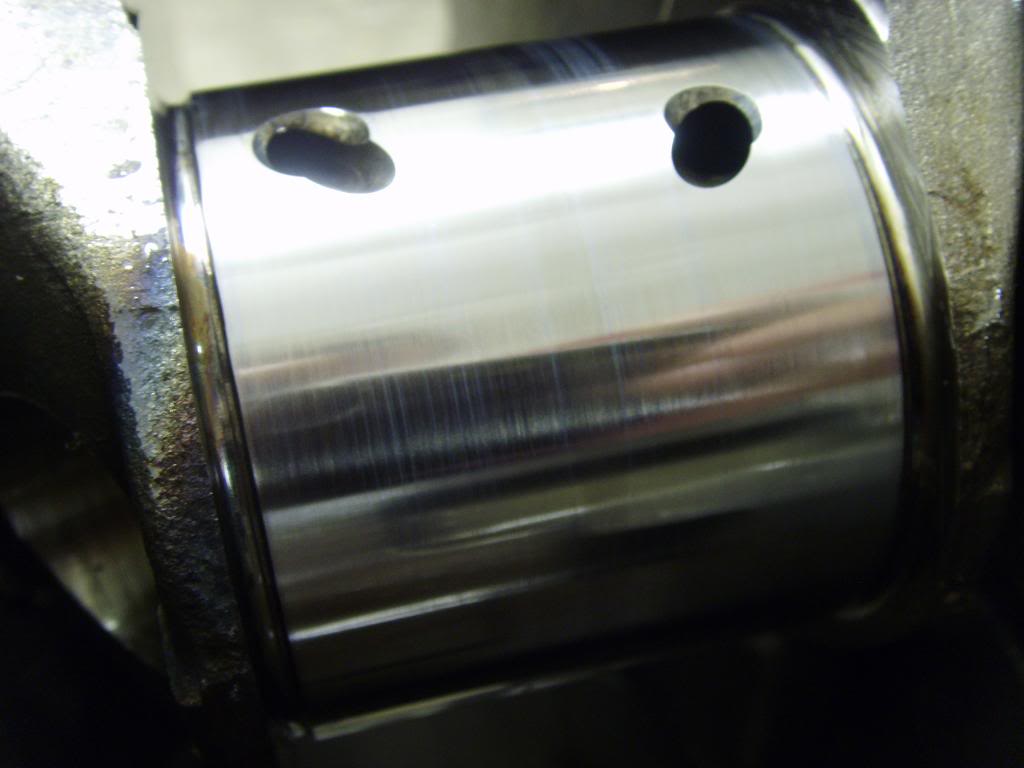

Crank shaft journals:

Shame to tear such a nice engine apart. Totally no wear, signs of wear or any indication that wear will arise.

Few parts collected already.

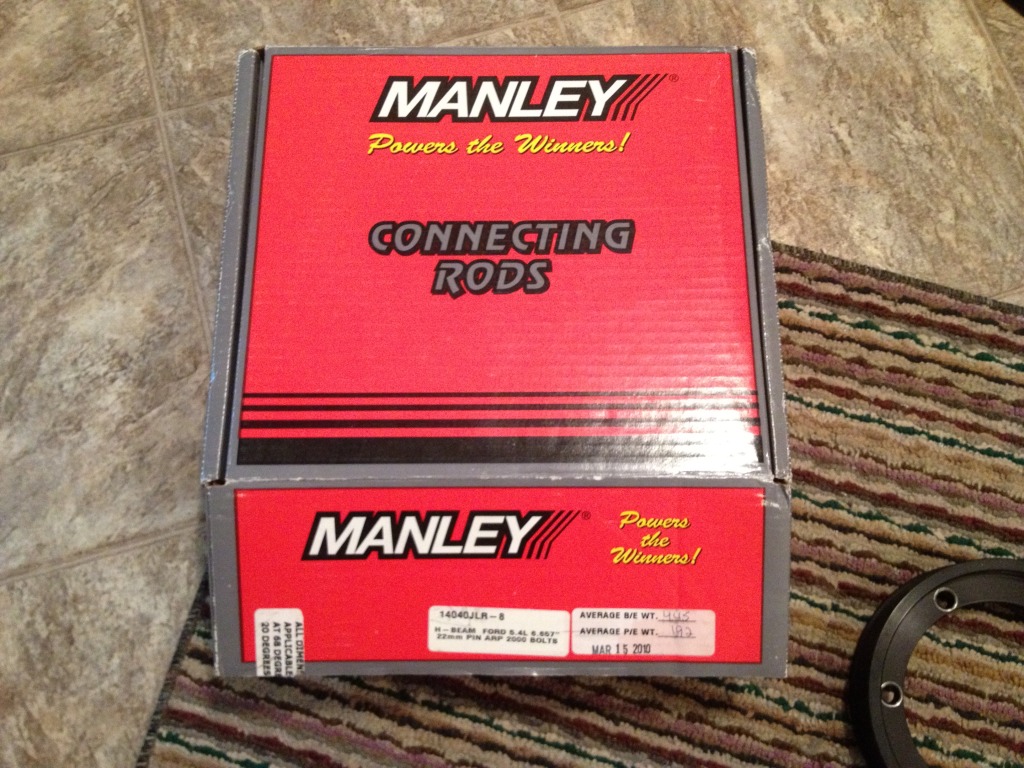

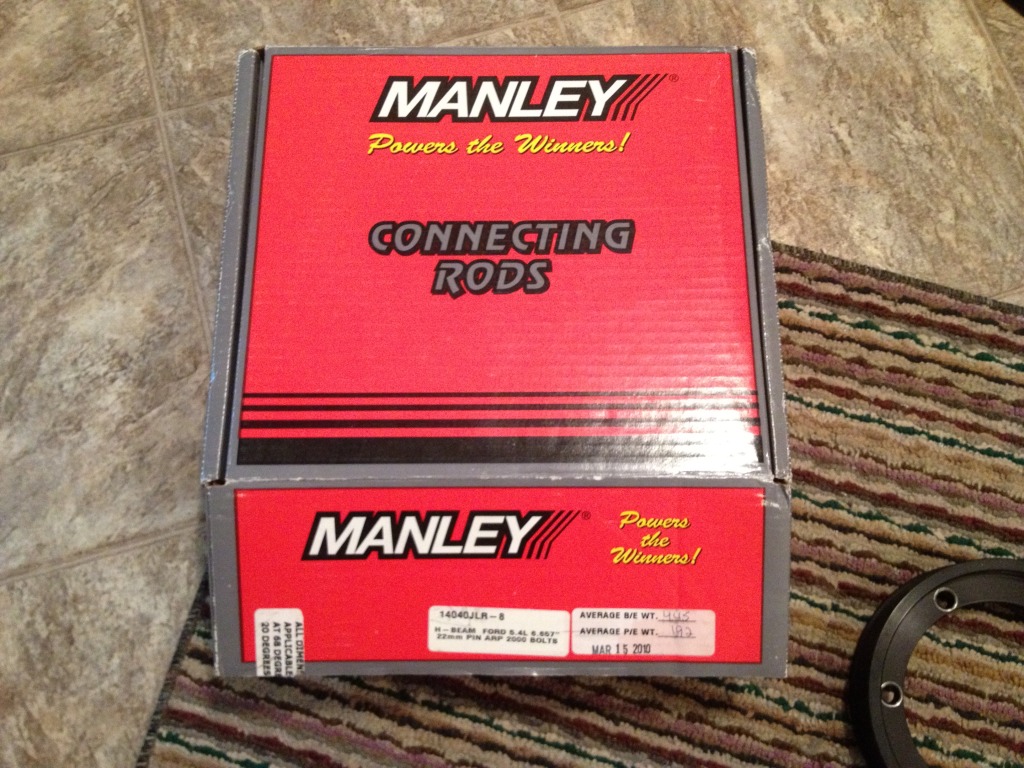

Manley H-Beams:

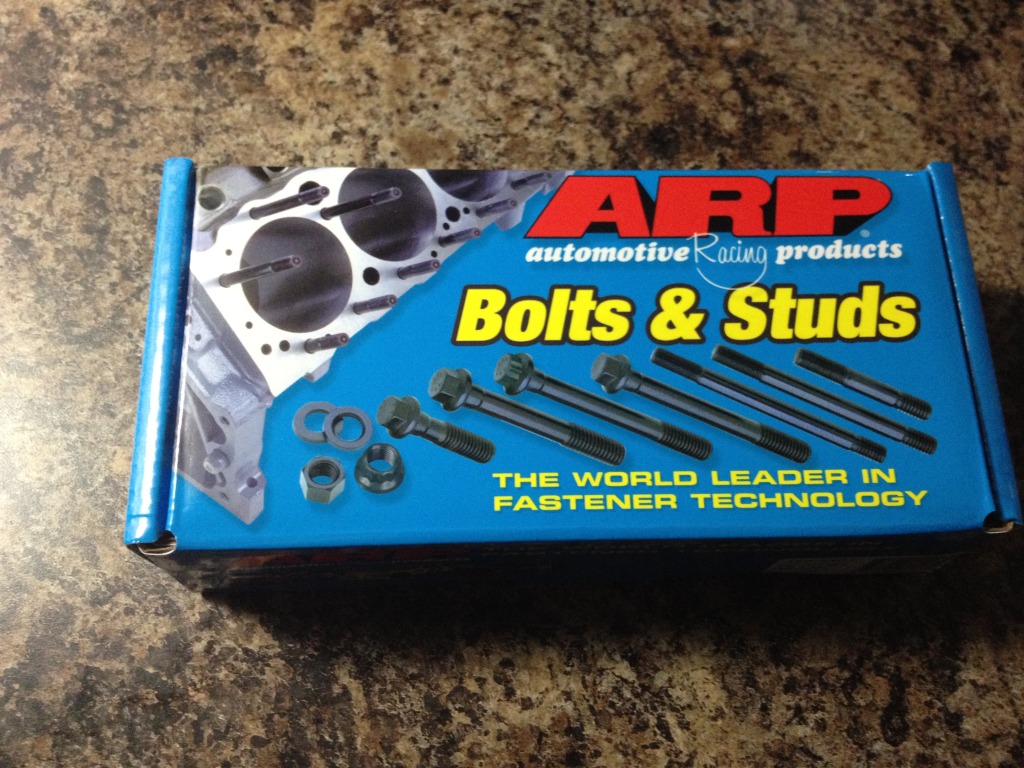

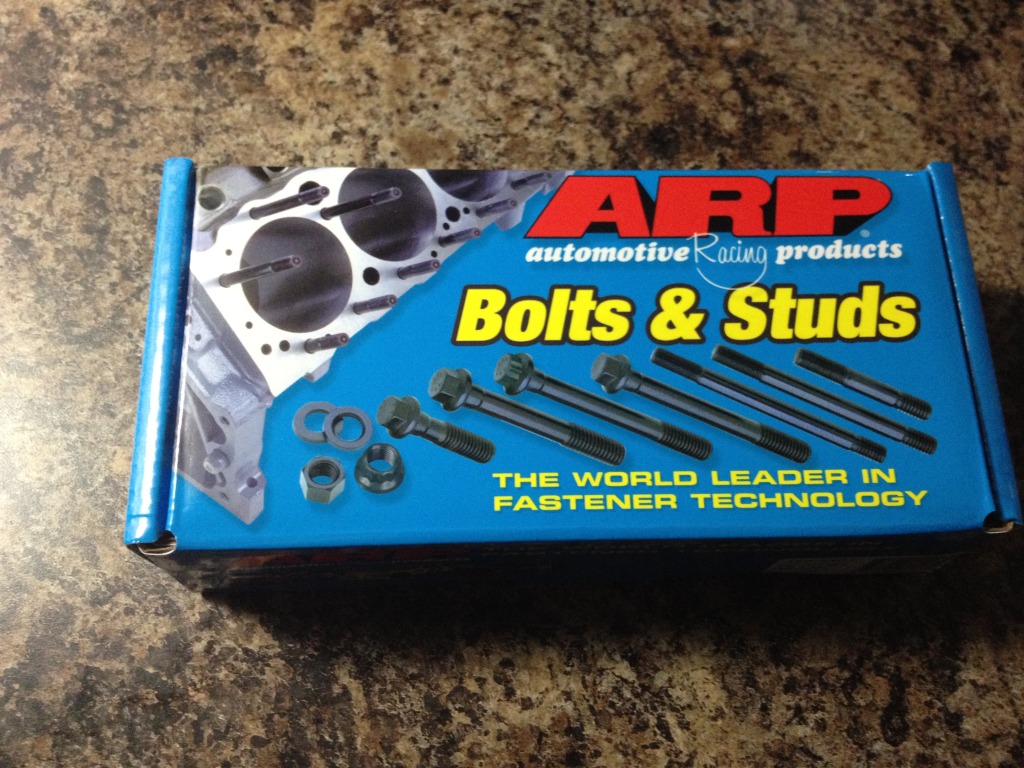

ARP mains & Head studs (12 point) & Fel-Pro MLS.

Also have allot if other parts for this build.

Heads are getting stripped and CNC'ed soon enough

The block will be sent away, hot dipped and might have the Mains line honed to accommodate the ARP Mains.

Anyhow I managed to find an 09 long block for under a grand.

Block:

Heads:

Started to strip: Cold crack Big end caps.

Pistons: Big ends are just like brand new.

Crank shaft journals:

Shame to tear such a nice engine apart. Totally no wear, signs of wear or any indication that wear will arise.

Few parts collected already.

Manley H-Beams:

ARP mains & Head studs (12 point) & Fel-Pro MLS.

Also have allot if other parts for this build.

Heads are getting stripped and CNC'ed soon enough

The block will be sent away, hot dipped and might have the Mains line honed to accommodate the ARP Mains.

#5

Hope to keep the pistons 3.552 as the bores look real real good .. No scoring or Heat marks in there .. The odd Blemish ..

The Lump was pulled and replaced with a Built block and Ford Racing heads I think!

Started to strip heads.

Cams: (Gonna try and sell them soon)

Heads: Havent got a Valve spring compressor and dont think the 'Deep socket & Hammer' trick will work on all 24.

RIGHT!!! Not sure about the heads now .. Some say a CNC & Big Valve job is only worth it for BIG HP applications? Some say a nice Cam and Spring job should work for a DD / Street truck?

What about uprated Rollers & Lifters? Again some say they only need to be uprated if you spin this engine faster than usual?

What do you guys think? Sure appreciate some input ...

The Lump was pulled and replaced with a Built block and Ford Racing heads I think!

Started to strip heads.

Cams: (Gonna try and sell them soon)

Heads: Havent got a Valve spring compressor and dont think the 'Deep socket & Hammer' trick will work on all 24.

RIGHT!!! Not sure about the heads now .. Some say a CNC & Big Valve job is only worth it for BIG HP applications? Some say a nice Cam and Spring job should work for a DD / Street truck?

What about uprated Rollers & Lifters? Again some say they only need to be uprated if you spin this engine faster than usual?

What do you guys think? Sure appreciate some input ...

Last edited by Ross-FX4; 01-02-2013 at 05:17 PM.

#6

Good blower cam will work wonders with the springs recommended for it to go with it. You won't be turning this motor past 6k (correct me if I'm wrong) and as a steet DD how often and how long will you be in that rpm range are the 2 questions I would consider before purchasing uprated rollers and lifters. Honestly they shouldn't be needed.

A port job will help but what kind of power do you want to make verses how much this procedure cost? A good polish job which you could do yourself will work well and net you some benefit. Also a port job on the heads that exceeds the port size of the intake runners would not benefit you.

Big valves. Already have 2 intake valves that do a great job and with the added lift and duration from the cam they will flow plenty of air. Maybe increase the exhaust valve size. My plan is to invest money in exhaust valves that won't melt at 1515F and then see what kind of money I have left for larger valves.

Just my thoughts .02.

A port job will help but what kind of power do you want to make verses how much this procedure cost? A good polish job which you could do yourself will work well and net you some benefit. Also a port job on the heads that exceeds the port size of the intake runners would not benefit you.

Big valves. Already have 2 intake valves that do a great job and with the added lift and duration from the cam they will flow plenty of air. Maybe increase the exhaust valve size. My plan is to invest money in exhaust valves that won't melt at 1515F and then see what kind of money I have left for larger valves.

Just my thoughts .02.

#7

Good blower cam will work wonders with the springs recommended for it to go with it. You won't be turning this motor past 6k (correct me if I'm wrong) and as a steet DD how often and how long will you be in that rpm range are the 2 questions I would consider before purchasing uprated rollers and lifters. Honestly they shouldn't be needed.

A port job will help but what kind of power do you want to make verses how much this procedure cost? A good polish job which you could do yourself will work well and net you some benefit. Also a port job on the heads that exceeds the port size of the intake runners would not benefit you.

Big valves. Already have 2 intake valves that do a great job and with the added lift and duration from the cam they will flow plenty of air. Maybe increase the exhaust valve size. My plan is to invest money in exhaust valves that won't melt at 1515F and then see what kind of money I have left for larger valves.

Just my thoughts .02.

A port job will help but what kind of power do you want to make verses how much this procedure cost? A good polish job which you could do yourself will work well and net you some benefit. Also a port job on the heads that exceeds the port size of the intake runners would not benefit you.

Big valves. Already have 2 intake valves that do a great job and with the added lift and duration from the cam they will flow plenty of air. Maybe increase the exhaust valve size. My plan is to invest money in exhaust valves that won't melt at 1515F and then see what kind of money I have left for larger valves.

Just my thoughts .02.

Power wise: IDE love 1000RW like every one ha ha.

But iam just looking to add the 4psi ring and maybe a 3.2 upper for 15psi boost. Although A port job, OBX headers will suck some psi from the 10 already in there.

Not planning in spinning the engine to fast. 6k would be the ceiling dependant on the tuners input / advise / recommendation's.

Your right again, biggest gains are on the exhaust side so maybe custom head work would be the best option. Along with a higher lift cam should work well. BUT going all out would give me a future proof top end.

Talked to a machine shop about a little work on the block. Will get back.

Trending Topics

#10

I will check MMR out later thanks!

HUITT: Haven't seen you post for a while. Forgot you had a built 3v.

The block is crated and might be going to the engine shop tomorrow (Last day off for me) They also talked about the heads. Open the exhaust up was the topic. Apparently they are building a Twin Turbo 4.6 for a pick up! See if I can get a pic / Info.

HUITT: Haven't seen you post for a while. Forgot you had a built 3v.

The block is crated and might be going to the engine shop tomorrow (Last day off for me) They also talked about the heads. Open the exhaust up was the topic. Apparently they are building a Twin Turbo 4.6 for a pick up! See if I can get a pic / Info.

#11

Dropped the block, Heads and associated parts off at the machine shop.

First impressions are a Stock bore Manley piston.

Not sure on dish as they are gonna mess with the heads. Talked about removing material around the valves etc then measure CC. Manley oversize Exhaust valve for sure and standard intakes. Then a price for some CompCam Blower cams, Valve springs & Retainers, Also a Comp phaser limiter kit.

Had a quick look at the 4.6 3V Turbo but was more interested in a 1800HP Mopar big block engine on a stand.

1) Block cleaning.

2) Bores measured and a Piston specific hone.

3) Alignment home on the mains and crank polish (Bearing specific)

4) Possible assembly & Rotating balance if the price is right.

5) Head polish, Manley valve(s) Cam etc MAYBE!

Spoke to the guy for ages. Talked about all aspects of the build and possible upgrades, down grades and future proof work.

Should hear back on Monday about what's required.

First impressions are a Stock bore Manley piston.

Not sure on dish as they are gonna mess with the heads. Talked about removing material around the valves etc then measure CC. Manley oversize Exhaust valve for sure and standard intakes. Then a price for some CompCam Blower cams, Valve springs & Retainers, Also a Comp phaser limiter kit.

Had a quick look at the 4.6 3V Turbo but was more interested in a 1800HP Mopar big block engine on a stand.

1) Block cleaning.

2) Bores measured and a Piston specific hone.

3) Alignment home on the mains and crank polish (Bearing specific)

4) Possible assembly & Rotating balance if the price is right.

5) Head polish, Manley valve(s) Cam etc MAYBE!

Spoke to the guy for ages. Talked about all aspects of the build and possible upgrades, down grades and future proof work.

Should hear back on Monday about what's required.

#12

#13

Oh well the option to remove the VVT altogether.

I don't wanna go lower than 9 CR. 18CC dish was mentioned but that's far to much. Possibly -6.5's that would give around 9.33:1 dependant on the head CC once the work has been completed.

Could get 9.5 with a flat top if the head CC is opened up enough.

I don't wanna go lower than 9 CR. 18CC dish was mentioned but that's far to much. Possibly -6.5's that would give around 9.33:1 dependant on the head CC once the work has been completed.

Could get 9.5 with a flat top if the head CC is opened up enough.