P0171 and P0174 again with a twist.

#1

P0171 and P0174 again with a twist.

Before anyone hammers me on this one which has been gone over and over again, read through before submitting the standard answer. Hopefully one of the pros here can help me out because i'm baffeled on this one.

The Victim: Me

The Defendant: 1998 Expedition 5.4 2WD

The symptom (and keep in mind this is my last thing wrong with this truck and it's off to inspection) Lean codes 0171 and 0174.

What has happened: I bought this guy used as a distress sale. I'm trying to get it to 100% and sell to some needy family. Yes, I do this for fun and not for profit in my spare time. With the economy as it is, there are more and more people needing a good used vehicle so I like to sell them as such.

When I got this, it was a total POS, threw more codes than a single ink pen could write. I've repaired everything wrong with this truck (New COP's, new plugs, new filters, cleaned injectors, new tires, brakes, wiperblades, etc...)

This truck has 165k on it.

I am left with these 2 codes and it will not pass inspection with them. Everything feels great on it as far as idle etc. I have replaced the #2 bank cat on it and I can't pay someone for passing it and remove the CEL bulb, that isn't right so i'm at the stumped point on this one.

I checked the vacuum elbow, it's good. I replaced the PCV and it operates properly, sprayed carb cleaner on everything and got no raised idle. The PCV hose is pulling alot of vacuum at idle and stumbles hard (like it should) if I let the air in. I checked the rail pressure which is at 28psi at idle. When I tap the throttle, the first 2 times or so it would drop to 22psi then up to 40psi. If I disconnect the vacuum to the FPR, it goes and holds at 40psi.

I have not pulled the TB and cleaned it uet so I thought I could post up what I have and hopefully someone alot smarter than I am could see what's wrong right away and save me some time and headache.

The last freeze frame reads this:

P0171

1838 RPM

Load 51.7%

Coolant 163

Short term trim #1 10.1%

Long term trim #1 25.0%

Short term trim #2 10.1%

Long term trim #2 25.0%

Short term trim #3 60.9%

Long term trim #3 -44.0%

Long term trim #4 -39.5%

Short term trim #4 55.4%

Speed 13mph

Closed loop

I can see that LT #3 and #4 are freaking this out, I just don't know what they are telling me is wrong.

Can anyone help?

TIA

The Victim: Me

The Defendant: 1998 Expedition 5.4 2WD

The symptom (and keep in mind this is my last thing wrong with this truck and it's off to inspection) Lean codes 0171 and 0174.

What has happened: I bought this guy used as a distress sale. I'm trying to get it to 100% and sell to some needy family. Yes, I do this for fun and not for profit in my spare time. With the economy as it is, there are more and more people needing a good used vehicle so I like to sell them as such.

When I got this, it was a total POS, threw more codes than a single ink pen could write. I've repaired everything wrong with this truck (New COP's, new plugs, new filters, cleaned injectors, new tires, brakes, wiperblades, etc...)

This truck has 165k on it.

I am left with these 2 codes and it will not pass inspection with them. Everything feels great on it as far as idle etc. I have replaced the #2 bank cat on it and I can't pay someone for passing it and remove the CEL bulb, that isn't right so i'm at the stumped point on this one.

I checked the vacuum elbow, it's good. I replaced the PCV and it operates properly, sprayed carb cleaner on everything and got no raised idle. The PCV hose is pulling alot of vacuum at idle and stumbles hard (like it should) if I let the air in. I checked the rail pressure which is at 28psi at idle. When I tap the throttle, the first 2 times or so it would drop to 22psi then up to 40psi. If I disconnect the vacuum to the FPR, it goes and holds at 40psi.

I have not pulled the TB and cleaned it uet so I thought I could post up what I have and hopefully someone alot smarter than I am could see what's wrong right away and save me some time and headache.

The last freeze frame reads this:

P0171

1838 RPM

Load 51.7%

Coolant 163

Short term trim #1 10.1%

Long term trim #1 25.0%

Short term trim #2 10.1%

Long term trim #2 25.0%

Short term trim #3 60.9%

Long term trim #3 -44.0%

Long term trim #4 -39.5%

Short term trim #4 55.4%

Speed 13mph

Closed loop

I can see that LT #3 and #4 are freaking this out, I just don't know what they are telling me is wrong.

Can anyone help?

TIA

#2

Before anyone hammers me on this one which has been gone over and over again, read through before submitting the standard answer. Hopefully one of the pros here can help me out because i'm baffeled on this one.

The Victim: Me

The Defendant: 1998 Expedition 5.4 2WD

The symptom (and keep in mind this is my last thing wrong with this truck and it's off to inspection) Lean codes 0171 and 0174.

What has happened: I bought this guy used as a distress sale. I'm trying to get it to 100% and sell to some needy family. Yes, I do this for fun and not for profit in my spare time. With the economy as it is, there are more and more people needing a good used vehicle so I like to sell them as such.

When I got this, it was a total POS, threw more codes than a single ink pen could write. I've repaired everything wrong with this truck (New COP's, new plugs, new filters, cleaned injectors, new tires, brakes, wiperblades, etc...)

This truck has 165k on it.

I am left with these 2 codes and it will not pass inspection with them. Everything feels great on it as far as idle etc. I have replaced the #2 bank cat on it and I can't pay someone for passing it and remove the CEL bulb, that isn't right so i'm at the stumped point on this one.

I checked the vacuum elbow, it's good. I replaced the PCV and it operates properly, sprayed carb cleaner on everything and got no raised idle. The PCV hose is pulling alot of vacuum at idle and stumbles hard (like it should) if I let the air in. I checked the rail pressure which is at 28psi at idle. When I tap the throttle, the first 2 times or so it would drop to 22psi then up to 40psi. If I disconnect the vacuum to the FPR, it goes and holds at 40psi.

I have not pulled the TB and cleaned it uet so I thought I could post up what I have and hopefully someone alot smarter than I am could see what's wrong right away and save me some time and headache.

The last freeze frame reads this:

P0171

1838 RPM

Load 51.7%

Coolant 163

Short term trim #1 10.1%

Long term trim #1 25.0%

Short term trim #2 10.1%

Long term trim #2 25.0%

Short term trim #3 60.9%

Long term trim #3 -44.0%

Long term trim #4 -39.5%

Short term trim #4 55.4%

Speed 13mph

Closed loop

I can see that LT #3 and #4 are freaking this out, I just don't know what they are telling me is wrong.

Can anyone help?

TIA

The Victim: Me

The Defendant: 1998 Expedition 5.4 2WD

The symptom (and keep in mind this is my last thing wrong with this truck and it's off to inspection) Lean codes 0171 and 0174.

What has happened: I bought this guy used as a distress sale. I'm trying to get it to 100% and sell to some needy family. Yes, I do this for fun and not for profit in my spare time. With the economy as it is, there are more and more people needing a good used vehicle so I like to sell them as such.

When I got this, it was a total POS, threw more codes than a single ink pen could write. I've repaired everything wrong with this truck (New COP's, new plugs, new filters, cleaned injectors, new tires, brakes, wiperblades, etc...)

This truck has 165k on it.

I am left with these 2 codes and it will not pass inspection with them. Everything feels great on it as far as idle etc. I have replaced the #2 bank cat on it and I can't pay someone for passing it and remove the CEL bulb, that isn't right so i'm at the stumped point on this one.

I checked the vacuum elbow, it's good. I replaced the PCV and it operates properly, sprayed carb cleaner on everything and got no raised idle. The PCV hose is pulling alot of vacuum at idle and stumbles hard (like it should) if I let the air in. I checked the rail pressure which is at 28psi at idle. When I tap the throttle, the first 2 times or so it would drop to 22psi then up to 40psi. If I disconnect the vacuum to the FPR, it goes and holds at 40psi.

I have not pulled the TB and cleaned it uet so I thought I could post up what I have and hopefully someone alot smarter than I am could see what's wrong right away and save me some time and headache.

The last freeze frame reads this:

P0171

1838 RPM

Load 51.7%

Coolant 163

Short term trim #1 10.1%

Long term trim #1 25.0%

Short term trim #2 10.1%

Long term trim #2 25.0%

Short term trim #3 60.9%

Long term trim #3 -44.0%

Long term trim #4 -39.5%

Short term trim #4 55.4%

Speed 13mph

Closed loop

I can see that LT #3 and #4 are freaking this out, I just don't know what they are telling me is wrong.

Can anyone help?

TIA

2- your a heck of nice guy if your doing this to help ppl out for no profit.

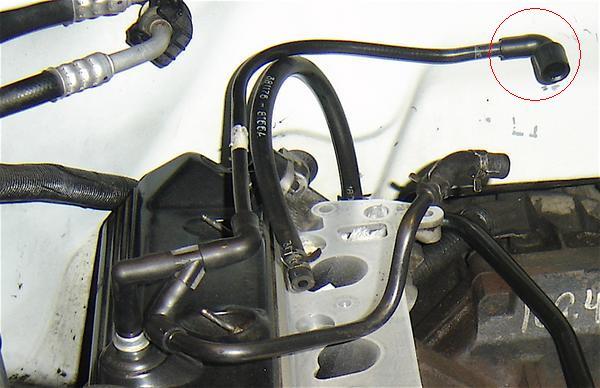

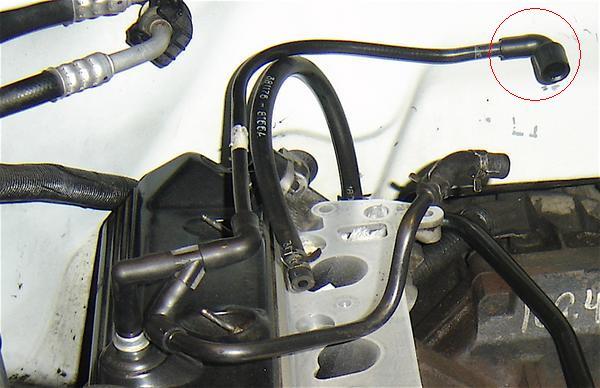

3- I went through this same nightmare about a year ago. There were ppl on here who guided me through alot of what you already did. A couple things come to mind. Did you clean the MAF Sensor yet with a good cleaner. I used CR Electronics cleaner and ended up tearing it right down to get a good look and clean shot at the sensor wires. I also removed my PCV assembly and really thought that I had no leaks in it anywhere, and thoroughly checked the rubber "L" connector that connects to the rear of the throttle body. After thinking I had it fixed, I drove it for a few weeks and about 400 miles and the CEL kicked those codes out again. Frustrated, I re-cleaned the MAF, ran to the local dealership and purchased the the entire PCV Assembly for $28.00. I installed the new assembly, put everything back together and I have not had those codes come back since.

I do remember that the rubber elbow was pretty soft, spongy and had a dry-rot look to it, with what looked like some surface cracks. The new elbow that came on the assembly was definately more rigid. I looked at that elbow over a few times and could not find a hole in it. Go figure, it fixed my problem.

This is all I can offer for you. You already have done everything that I checked, tested and went through.

Good Luck with it.

By the way, what Scantool you using. That Freeze Frame Data doesn't look familiar to me. The Layout of it anyways.

TJK

#3

I forgot to mention that I did clean the MAF. When I got it home the thing wouldn't idle at all. I dumped 10 gallons of fresh gas in it and a full can of seafoam and played with the gas pedal until I was certain I had new fuel running through, it still wouldn't idle on its own. Then for some odd reason, I grabbed the new air filter out of its box, swapped it and wouldn't you know it, the thing would run on its own after that. Diagnosing the miss and low power, I pulled the MAF. It's a re-man unit so someone was playing around in there at some point. I cleaned it completely with CRC MAF cleaner at least a couple times. Also while in there looking for leaks, I noticed something not right. The *** end of the MAF (away from the mounting flange) does not go through the air box housing and there is a 1/8" gap. The intake hose also does not connect directly to the MAF, there are holes where I figured air was leaking around the sensor and possibly pulling from the MAF wire boot. I greased the crap out of that rubber block last night thinking that was it. The truck threw a code right after during my test drive. I'm not sure if there is supposed to be some sort of gasket in there but from the looks of the design, either the engineer was high when that box was designed or there is some error factor going on with MAF sensitivity. Or the possibility exists that there is a missing piece i'm unaware of.

Other than that, the entire intake tract looks and feels tight everywhere. I also am not looking deeper into that avenue simply because during the course of the standard tune up, the plugs were reading a bit on the lean side. Not totally white, but not tan either. The electrode was closer to lean. So I took from this that this guy is lean at heavy load as indicated by the trims pulled, and where the codes happen, and it's running fine at light load. To me, this would indicate a vacuum leak or low fuel pressure/flow. I wanted to post the trims as I don't know what #3 and #4 are, never seen those before. Those are so far apart that I believe this is telling me what's wrong with it.

The scanner is an Actron CP9175 at the time, was the only readily available scanner that did CAN bus and would do an emissions readyness test. I hate going to get an inspection and they tell me to drive around for 50 miles. This tests everything any inspection station will test.

Thanks for the props on doing this stuff for free, I do charge for parts, tests, etc.. but in todays economy, alot of good folks lost their retirement, job, and home. Most of these people are hurting bad and can't afford a reliable car or truck and wind up at smiling joes used car lot, paying 18% on a note for a patched together junker. Look at the stock prices for Kragen, Auto Zone, Pep Boys and you'll see that those places are very profitable right now. This is why and I like to fix things. My wife gets to drive around in something else for a month or I do, and we are able to a: buy something from someone needing money fast, and b: help out someone in need by getting them something properly running that will last them at least a couple years until they can get back on their feet. It's a win/win for all, i'm just fronting a little cash and time, so it's no skin off my back so why not?

I would guess that an easy way to test the PCV tubing though would be to block off the manifold first and see what happens unless there is something that can get hurt that way? I can really drive this around the block and force a code.

Other than that, the entire intake tract looks and feels tight everywhere. I also am not looking deeper into that avenue simply because during the course of the standard tune up, the plugs were reading a bit on the lean side. Not totally white, but not tan either. The electrode was closer to lean. So I took from this that this guy is lean at heavy load as indicated by the trims pulled, and where the codes happen, and it's running fine at light load. To me, this would indicate a vacuum leak or low fuel pressure/flow. I wanted to post the trims as I don't know what #3 and #4 are, never seen those before. Those are so far apart that I believe this is telling me what's wrong with it.

The scanner is an Actron CP9175 at the time, was the only readily available scanner that did CAN bus and would do an emissions readyness test. I hate going to get an inspection and they tell me to drive around for 50 miles. This tests everything any inspection station will test.

Thanks for the props on doing this stuff for free, I do charge for parts, tests, etc.. but in todays economy, alot of good folks lost their retirement, job, and home. Most of these people are hurting bad and can't afford a reliable car or truck and wind up at smiling joes used car lot, paying 18% on a note for a patched together junker. Look at the stock prices for Kragen, Auto Zone, Pep Boys and you'll see that those places are very profitable right now. This is why and I like to fix things. My wife gets to drive around in something else for a month or I do, and we are able to a: buy something from someone needing money fast, and b: help out someone in need by getting them something properly running that will last them at least a couple years until they can get back on their feet. It's a win/win for all, i'm just fronting a little cash and time, so it's no skin off my back so why not?

I would guess that an easy way to test the PCV tubing though would be to block off the manifold first and see what happens unless there is something that can get hurt that way? I can really drive this around the block and force a code.

#4

MAF - Its okay. Two nuts hold it to the plastic backing plate, NO gasket needed. Not sure what else your talking about ?

You mentioned a mis right ? Well, that has to be handled first as this could be reason for lean issues.

Personally, I think you need intake gaskets. Then again, sounds like your running Autolight plugs lol. If so, those need to be replaced w/a set of Motorcraft plugs.

A 98 with those miles = Intake gaskets, Forward O2 sensors, the correct plugs and most likley a set of coils will do wonders for her.

Those heads pit, you'll probably notice this if you do the gaskets. You can fix yourself.

We can tell you where to get the parts cheap.

You mentioned a mis right ? Well, that has to be handled first as this could be reason for lean issues.

Personally, I think you need intake gaskets. Then again, sounds like your running Autolight plugs lol. If so, those need to be replaced w/a set of Motorcraft plugs.

A 98 with those miles = Intake gaskets, Forward O2 sensors, the correct plugs and most likley a set of coils will do wonders for her.

Those heads pit, you'll probably notice this if you do the gaskets. You can fix yourself.

We can tell you where to get the parts cheap.

#5

#6

(learned this from personal experience)

If there are any gaps, holes etc. in the air intake duct from the filter to the

throttle body, it will throw those lean codes.

When I did my COP & Plug change awhile back, I left part of the tunnel partially disconnected (by accident) and during my 1st test drive it threw the CEL on. I pulled over and found the problem. Went home, cleared the codes, tightened up the intake duct properly and then went on my test drive again, no problem.

Hope this helps !

#7

Trending Topics

#8

By the way, I just re-read your post, I have a little concern about you applying grease around the connector block that fits into the bottom of the MAF housing. I am not quite sure if any of the grease will get sucked by and into the system, but it would concern me.

There is some serious vacuum/suction being drawn through the Air Intake Duct.

Just a thought !

There is some serious vacuum/suction being drawn through the Air Intake Duct.

Just a thought !

#9

MAF - Its okay. Two nuts hold it to the plastic backing plate, NO gasket needed. Not sure what else your talking about ?

You mentioned a mis right ? Well, that has to be handled first as this could be reason for lean issues.

Personally, I think you need intake gaskets. Then again, sounds like your running Autolight plugs lol. If so, those need to be replaced w/a set of Motorcraft plugs.

A 98 with those miles = Intake gaskets, Forward O2 sensors, the correct plugs and most likley a set of coils will do wonders for her.

Those heads pit, you'll probably notice this if you do the gaskets. You can fix yourself.

We can tell you where to get the parts cheap.

You mentioned a mis right ? Well, that has to be handled first as this could be reason for lean issues.

Personally, I think you need intake gaskets. Then again, sounds like your running Autolight plugs lol. If so, those need to be replaced w/a set of Motorcraft plugs.

A 98 with those miles = Intake gaskets, Forward O2 sensors, the correct plugs and most likley a set of coils will do wonders for her.

Those heads pit, you'll probably notice this if you do the gaskets. You can fix yourself.

We can tell you where to get the parts cheap.

I was going to remove the EGR and clean it but whoever put 2 8mm bolts in a EGR wasn't expecting me to get it off without breaking the bolts. I didn't try too hard being that replacement bolts need to be sourced first, then I can break them off

So I guess the consensus is manifold gaskets next? I have new forward o2 sensors but did not put them in, the old ones seem to be reading correctly as-is.

#10

Join Date: Jun 2002

Location: Under the flightpath of old ORD 22R

Posts: 10,511

Likes: 0

Received 7 Likes

on

7 Posts

jbrew,

Been a long time, but isn't the MAFS held inplace by 4 screws ?

Factory MAFS mounting

I seem to recall a gasket on the MAFS, but this might have been included with the FPIK kit ?? I used a MAFS adapter plate to a JLP filter on my 2001 ( actually dad is still using it ).

Also, I see no note if the IAT is installed correctly. If this or the 2 hoses by the throttle body ( under the cover ) are loose, this is un mettered air getting into the system.

Not sure if the "mis fire" is actually a misfire, the CEL would be blinking and a P030x code should also show. I am guessing this is a stumble more so, which could point to a dirty IAC valve ( which I see no note of being checked / cleaned ).

The other specific item ( usually the cause ) is no mention of checking the vac lines to the EGR ( did I miss that ) ?

Maybe it is so dirty it is held open at any TPS, and this could be un-metered air getting into the system ?

Also check the fuel cap, and the dip stick. Both of these can cause un metered air in the system. Full list if you did not run everything or find it

https://www.f150online.com/forums/v8...ine-light.html

Also bad assumption, is this the factory intake still ?? Don't want to assume.

Been a long time, but isn't the MAFS held inplace by 4 screws ?

Factory MAFS mounting

I seem to recall a gasket on the MAFS, but this might have been included with the FPIK kit ?? I used a MAFS adapter plate to a JLP filter on my 2001 ( actually dad is still using it ).

Also, I see no note if the IAT is installed correctly. If this or the 2 hoses by the throttle body ( under the cover ) are loose, this is un mettered air getting into the system.

Not sure if the "mis fire" is actually a misfire, the CEL would be blinking and a P030x code should also show. I am guessing this is a stumble more so, which could point to a dirty IAC valve ( which I see no note of being checked / cleaned ).

The other specific item ( usually the cause ) is no mention of checking the vac lines to the EGR ( did I miss that ) ?

Maybe it is so dirty it is held open at any TPS, and this could be un-metered air getting into the system ?

Also check the fuel cap, and the dip stick. Both of these can cause un metered air in the system. Full list if you did not run everything or find it

https://www.f150online.com/forums/v8...ine-light.html

Also bad assumption, is this the factory intake still ?? Don't want to assume.

#12

What's up Skully - Yes, the Sensor itself is Machine screwed in (4 Safety Torx). I thought the OP may be referring to the gap where the MAF cylinder connects to that big clip in insert in your pic, which only fits one way on two pegs w/two 10 mm screws- (btw - where in the hell did you find that 2nd pic and what is it? lol). - Some kind of invention lol.

Anyway, right! OP could be referring to what you mentioned just as easy, except he mentioned an 1/8" gap.? The 1/8" gap lead me to believe he was talking about the cylinder - could be wrong.

If so, there isn't a perimeter gasket for the sensor itself, but there is an O-Ring on the wire cylinder itself that does a great job of sealing the sensor. I have never seen a leak here, but it's possible. If the perimeter seam was sealed, it didn't need to be, but it won't hurt anything. As long as turbulence won't cause it to travel. I have to have a pic of the sealing ring somewhere... Yea, O-Ring pictured here -

NOTE: After market Intake ^^^^ - NOT STOCK.

__________________________________________________ ____

You have a great Hit List here Skully -

It's a 2001 list,- the 01's didn't have an ECT. The 98's did. So, add the ECT to the list, it also plays a role with your A/F mix. The ECT bulb can get corroded on the bottom. That happened with my 98 - about 100,000 miles ago when I was in the 160's.

Yea the IAT as well. The grommet can get dry rotted and crack. Just move the IAT around in place and watch for cracks in the grommet. On the hand, he mentioned the everything was tight on the intake, sooo, Idunno.

A leak in the EVAP system usually generates a 400 series code, but it's possible for unmetered air to enter the plenum via EVAP since it's plumbed into it. Babcox has a good right up on the EVAP -

http://www.babcox.com/editorial/us/us10126.htm

Leaky O2's - I've seen that one generate lean codes.

What happens allot on the 98's is the EGR pipe itself rusts out at the manifold. Also the oil dipstick rusts out between the manifold and the head. I've come across that, but no DTC's resulted from it.

Lot's to check, but the most common when both banks test positive for lean = The PCV elbow by the firewall - Pinhole problem -

BTW - Off subject, but check this out Skully - http://fordfuelinjection.com/?p=7 Great site!

Anyway, right! OP could be referring to what you mentioned just as easy, except he mentioned an 1/8" gap.? The 1/8" gap lead me to believe he was talking about the cylinder - could be wrong.

If so, there isn't a perimeter gasket for the sensor itself, but there is an O-Ring on the wire cylinder itself that does a great job of sealing the sensor. I have never seen a leak here, but it's possible. If the perimeter seam was sealed, it didn't need to be, but it won't hurt anything. As long as turbulence won't cause it to travel. I have to have a pic of the sealing ring somewhere... Yea, O-Ring pictured here -

NOTE: After market Intake ^^^^ - NOT STOCK.

__________________________________________________ ____

You have a great Hit List here Skully -

DTC

P0174 - System to Lean (Bank 2) - see DTC P0171

DTC

P0171 - System to Lean (Bank 1)

Description

The Adaptive Fuel Strategy continuously monitors fuel delivery hardware. The test fails when the adaptive fuel tables reach a rich calibrated limit.

Possible Causes

Fuel system

Excessive fuel pressure.

Leaking /contaminated fuel injectors.

Leaking fuel pressure regulator.

Low fuel pressure or running out of fuel

Vapor recovery system.

Induction system:

- Air leaks after the MAF.

- Vacuum Leaks.

- PCV system.

- Improperly seated engine oil dipstick

EGR system:

- Leaking gasket.

- Stuck EGR valve.

Leaking diaphragm or EVR

Base Engine:

- Oil overfill.

- Cam timing.

- Cylinder compression.

- Exhaust leaks before or near the HO2Ss.

Diagnostic Aides

A SHRTFT-1,2 PID value between -25% to +35% and a LONGFT-1,2 PID value between -35% to +35% is acceptable. Reading beyond these values indicate a failure.

P0174 - System to Lean (Bank 2) - see DTC P0171

DTC

P0171 - System to Lean (Bank 1)

Description

The Adaptive Fuel Strategy continuously monitors fuel delivery hardware. The test fails when the adaptive fuel tables reach a rich calibrated limit.

Possible Causes

Fuel system

Excessive fuel pressure.

Leaking /contaminated fuel injectors.

Leaking fuel pressure regulator.

Low fuel pressure or running out of fuel

Vapor recovery system.

Induction system:

- Air leaks after the MAF.

- Vacuum Leaks.

- PCV system.

- Improperly seated engine oil dipstick

EGR system:

- Leaking gasket.

- Stuck EGR valve.

Leaking diaphragm or EVR

Base Engine:

- Oil overfill.

- Cam timing.

- Cylinder compression.

- Exhaust leaks before or near the HO2Ss.

Diagnostic Aides

A SHRTFT-1,2 PID value between -25% to +35% and a LONGFT-1,2 PID value between -35% to +35% is acceptable. Reading beyond these values indicate a failure.

It's a 2001 list,- the 01's didn't have an ECT. The 98's did. So, add the ECT to the list, it also plays a role with your A/F mix. The ECT bulb can get corroded on the bottom. That happened with my 98 - about 100,000 miles ago when I was in the 160's.

Yea the IAT as well. The grommet can get dry rotted and crack. Just move the IAT around in place and watch for cracks in the grommet. On the hand, he mentioned the everything was tight on the intake, sooo, Idunno.

A leak in the EVAP system usually generates a 400 series code, but it's possible for unmetered air to enter the plenum via EVAP since it's plumbed into it. Babcox has a good right up on the EVAP -

http://www.babcox.com/editorial/us/us10126.htm

Leaky O2's - I've seen that one generate lean codes.

What happens allot on the 98's is the EGR pipe itself rusts out at the manifold. Also the oil dipstick rusts out between the manifold and the head. I've come across that, but no DTC's resulted from it.

Lot's to check, but the most common when both banks test positive for lean = The PCV elbow by the firewall - Pinhole problem -

BTW - Off subject, but check this out Skully - http://fordfuelinjection.com/?p=7 Great site!

Last edited by jbrew; 03-27-2009 at 12:50 PM.

#13

Join Date: Jun 2002

Location: Under the flightpath of old ORD 22R

Posts: 10,511

Likes: 0

Received 7 Likes

on

7 Posts

That was back in 2002/2003 the FIPK design wars

I came up with using the tube from the K&N a MAFS adapter plate, and the filter from the JPL airram kit.

This is why I asked about a gasket on the MAFS plate, I thought I had one on there, but it could be from the K&N kit.

EDIT : Found it, the K&N kit had the gasket in it

27. Attach the mass air adapter to the mass air sensor using the gasket and provided hardware.

Cool site, thanks for the URL

Last edited by SSCULLY; 03-27-2009 at 12:56 PM.

#14

By the way, I just re-read your post, I have a little concern about you applying grease around the connector block that fits into the bottom of the MAF housing. I am not quite sure if any of the grease will get sucked by and into the system, but it would concern me.

There is some serious vacuum/suction being drawn through the Air Intake Duct.

Just a thought !

There is some serious vacuum/suction being drawn through the Air Intake Duct.

Just a thought !

I can take pictures of this later if needed but here is the reasoning and why it won't hurt.

The air filter seals against the MAF backing plate when you put the canister together. There is no real "seal" from the MAF backing plate to the MAF half of the canister. Air could possibly get past the backing plate. The area behind the backing plate is also shared with the MAF connector and gaping hole where that connector and rubber plug is. When you put the MAF into the canister (like after cleaning it) look at the opposite side of the MAF and where the incoming air would go. There is no seal on the back of the MAF. To me, this means that air could possibly leak around the MAF at this junction assuming there is a path of least resistance besides through that filter. The 2nd thing I was commenting on is that the hose connecting this half of the cannister to the intake is much larger than the MAF. This connection point at the back of the cannister would allow unmetered air into the intake, bypassing the MAF through the outer portion of the housing assuming there is a lesser resistance path for the air to take, thought of as the MAF connector sealing boot. This is why I went ahead and lightly greased the boot when reassembling it. If the boot were to leak grease into the intake, that grease would still bypass the MAF and thus not fouling the hot wire. It would simply get sucked into the intake and burned during normal combustion.

So at this point, I will try cleaning the EGR with the assumption that there is carbon built up and not closing completely, also assuming I get the bolts off after liquid wrench soaking. Then intake manifold gaskets after that.

#15

This is why I went ahead and lightly greased the boot when reassembling it. If the boot were to leak grease into the intake, that grease would still bypass the MAF and thus not fouling the hot wire. It would simply get sucked into the intake and burned during normal combustion..

The 1/8" gap is where ? lol. Look at the pic of the inside of the intake Skully posted. It that what your talking about? The MAF cylinder?

Just Suck Test the EGR operation. Here's what you do to test the EGR diaphragm/poppet valve operation. - Pull the green EVR vac line off the EGR valve while @ idle. Plug your own line into the valve. If you have a Mighty Vac tool , create vac (no more than 6 Hg). Idle should deflect immediately and the engine should almost stall. If nothing happens, - The diaphragm is toast or the EGR ports are clogged.

If you don't have a Vac tool, just attach a 3' section of hose to the valve and suck on it like your drinking a milkshake. Same thing should happen - Idle deflects/almost stalls. That tells you the valve is good.

If you break those bolts, those are 8-10's - A PITA to drill out, I have to use a Carbide burr to get those out lol.

If the ports are clogged, your going to have to remove the Throttle body to intake elbow AFTER you remove the EGR pipe connect. The EGR pipe connect may seem tough, but you can reef on that until you get it loose, -without damaging a thing. Once it's cracked loose, it spins off by hand.

NOTE: Don't attempt to clean the EGR valve. That Diaphram is sensitive as hell. Not very user friendly, trust me I know lol. - No more than 6 hg's.

This is a little much -

Last edited by jbrew; 03-27-2009 at 02:08 PM.