Pulley size calculations... go w/ me on this one

#1

Pulley size calculations... go w/ me on this one

First, I am trying to learn here and help out the community. I would appreciate someone who is good at math to check my numbers.

Unless I have come down with the last drop of rain, ratio is what drives the blower gearbox. The higher the ratio, the more the blower spins and the more HP we generate...

Second, I have a spreadsheet that I made up to do the calcualtions if someone wants to host it. It's not rocket science.

Ratio= Lower/Upper or: ratio*upper = lower

On to my rant...

I have seen and been told that the HD upper is 3.25 inches where the L is 2.93. It is also understood that we only make 6lbs where they make 8 so... (2lb difference)

We both have a stock lower of 7.4”. I will assume for the sake of my argument that we will leave the upper alone and concentrate on the lower pulley only.

For the record, I am interested in driving my 02HD supercharger at the same blower speed as a Lightning blower running a 4lb lower pulley. Using 8.5” as the measurement for a 4lb lower and 2.93 as the upper measurement on the L, this nets a drive ratio spinning the blower of 2.9010:1. Ok, so now let’s look at a 6lb lower (I have it) on the HD. Assuming the 3.25 inch measurement is correct (I need 100% proof positive information on this), then a 6lb lower (9”) nets a drive ratio of 2.7692:1 on the Harley.

Now for the shocker (assuming my math is correct): To obtain a 2.7692:1 ratio on the LIGHTNING blower upper (2.93”), the lower needs to be 8.11385”. That is slightly smaller than JL’s THREE POUND LOWER! Call it a 2.75lb lower… Remember, I want a 4lb equivalent here and I am getting 2.75ish pounds in equivalent L ratio…

Ok, so let’s look at the 8lb lower on the HD and the L. Given it is supposed to be 2lbs lower on the L, the 8lb lower with an HD upper should net 6lbs and actually, we net out at 3.0769:1. A 6lb lower on the L nets out at 3.0717. So, an 8lb lower is netting JUST OVER 6lbs of boost on the HD. Call it a 6 1/32 lb lower for the HD… So, this one is pretty close.

That means: In order for me to get the true 4lbs of boost over stock that I want, I would need, given a 3.25” upper and a ratio of 2.9010, an upper that is 9.4283” in diameter or roughly a 7lb lower (they rate them in .5 inch increments… 6lb=9”, 8”=10” so a 7lb would be 9,5”) The actual ratio of the 9.5 would net around 4 1/8 lbs of boost equivalent on a Lightning.

So, I guess what I am saying, is we need a 7lb pulley for the HD community…

And, for those wanting to run a lower pulley with no chip, it is understood that the L will run fine with a 2lb lower and no chip. Using a metco pulley, the ratio would be such that the JL 5lb lower will net slightly more than 2lbs using a metco (8inches) and about 1.9lbs on the JDM 2lb lower (7.8”)

Please comment if you have any input. I am going to talk to a couple of vendors and see if they are interested in making one.

Ken

Unless I have come down with the last drop of rain, ratio is what drives the blower gearbox. The higher the ratio, the more the blower spins and the more HP we generate...

Second, I have a spreadsheet that I made up to do the calcualtions if someone wants to host it. It's not rocket science.

Ratio= Lower/Upper or: ratio*upper = lower

On to my rant...

I have seen and been told that the HD upper is 3.25 inches where the L is 2.93. It is also understood that we only make 6lbs where they make 8 so... (2lb difference)

We both have a stock lower of 7.4”. I will assume for the sake of my argument that we will leave the upper alone and concentrate on the lower pulley only.

For the record, I am interested in driving my 02HD supercharger at the same blower speed as a Lightning blower running a 4lb lower pulley. Using 8.5” as the measurement for a 4lb lower and 2.93 as the upper measurement on the L, this nets a drive ratio spinning the blower of 2.9010:1. Ok, so now let’s look at a 6lb lower (I have it) on the HD. Assuming the 3.25 inch measurement is correct (I need 100% proof positive information on this), then a 6lb lower (9”) nets a drive ratio of 2.7692:1 on the Harley.

Now for the shocker (assuming my math is correct): To obtain a 2.7692:1 ratio on the LIGHTNING blower upper (2.93”), the lower needs to be 8.11385”. That is slightly smaller than JL’s THREE POUND LOWER! Call it a 2.75lb lower… Remember, I want a 4lb equivalent here and I am getting 2.75ish pounds in equivalent L ratio…

Ok, so let’s look at the 8lb lower on the HD and the L. Given it is supposed to be 2lbs lower on the L, the 8lb lower with an HD upper should net 6lbs and actually, we net out at 3.0769:1. A 6lb lower on the L nets out at 3.0717. So, an 8lb lower is netting JUST OVER 6lbs of boost on the HD. Call it a 6 1/32 lb lower for the HD… So, this one is pretty close.

That means: In order for me to get the true 4lbs of boost over stock that I want, I would need, given a 3.25” upper and a ratio of 2.9010, an upper that is 9.4283” in diameter or roughly a 7lb lower (they rate them in .5 inch increments… 6lb=9”, 8”=10” so a 7lb would be 9,5”) The actual ratio of the 9.5 would net around 4 1/8 lbs of boost equivalent on a Lightning.

So, I guess what I am saying, is we need a 7lb pulley for the HD community…

And, for those wanting to run a lower pulley with no chip, it is understood that the L will run fine with a 2lb lower and no chip. Using a metco pulley, the ratio would be such that the JL 5lb lower will net slightly more than 2lbs using a metco (8inches) and about 1.9lbs on the JDM 2lb lower (7.8”)

Please comment if you have any input. I am going to talk to a couple of vendors and see if they are interested in making one.

Ken

#2

ken800,

Here are some of my thoughts and ramblings on areas you touched with your posting (I hope you and others will forgive me if I am confused because boost in truck world might not be same as boost in my world of expertise and if I am talking out of my a**, I am not even dreaming that I understand how these things work, I am just guessing):

1) Assumption in your posting is that increase in boost is linearly related to pulley ratio. My gut feeling tells me it is not (I always can be wrong). Logic behind my gut feeling is following: Air doesn't like being compressed. Increase in energy needed to keep on compressing it is not linear to increase in pressure. To increase pressure twofold you need much more than twofold increase in energy spent. Ratio of pulleys determines just RPMs at which blower will be working. Therefore blower would need to spin much more than twice faster to create twofold increase in boost.

2) Does anyone know what are safe RPMs these blowers can spin on? That should be one of factors to take into account when deciding which pulley can be put on. Heavens forbid bearing seizes at bad moment or axle bends.

3) Assuming blower can take it next question is can engine (rods and everything) take it. Too many factors there but lets assume engine can take it. Now we come to trickiest area of it all and that is air/fuel mixture whose ratio we just changed by pumping in more air. More air in will mean leaner mixture and we all know what that can cause. We don't want that. We need to give it more fuel, change timings, what not. Stock That's where chips step in and try to handle all that. However, as we all know, things can go wrong.

Because of all of this I would like to say that which pulley will work safely is heavily going to be dependent on individual truck. Certain values might work for majority of people, but can make few unlucky ones very miserable. Of course, you gotta pay if you want to play and that is one of the risks you have to decide on. Therefore, having an option of 7lb pulley is not gonna hurt by default. But what I would like to see even more is something that would let us monitor behavior of a truck, either stock one or modded one, down the freeway (dyno is not real world) so we can say we know everything is OK vs we think we are OK.

ZoranC

Here are some of my thoughts and ramblings on areas you touched with your posting (I hope you and others will forgive me if I am confused because boost in truck world might not be same as boost in my world of expertise and if I am talking out of my a**, I am not even dreaming that I understand how these things work, I am just guessing):

1) Assumption in your posting is that increase in boost is linearly related to pulley ratio. My gut feeling tells me it is not (I always can be wrong). Logic behind my gut feeling is following: Air doesn't like being compressed. Increase in energy needed to keep on compressing it is not linear to increase in pressure. To increase pressure twofold you need much more than twofold increase in energy spent. Ratio of pulleys determines just RPMs at which blower will be working. Therefore blower would need to spin much more than twice faster to create twofold increase in boost.

2) Does anyone know what are safe RPMs these blowers can spin on? That should be one of factors to take into account when deciding which pulley can be put on. Heavens forbid bearing seizes at bad moment or axle bends.

3) Assuming blower can take it next question is can engine (rods and everything) take it. Too many factors there but lets assume engine can take it. Now we come to trickiest area of it all and that is air/fuel mixture whose ratio we just changed by pumping in more air. More air in will mean leaner mixture and we all know what that can cause. We don't want that. We need to give it more fuel, change timings, what not. Stock That's where chips step in and try to handle all that. However, as we all know, things can go wrong.

Because of all of this I would like to say that which pulley will work safely is heavily going to be dependent on individual truck. Certain values might work for majority of people, but can make few unlucky ones very miserable. Of course, you gotta pay if you want to play and that is one of the risks you have to decide on. Therefore, having an option of 7lb pulley is not gonna hurt by default. But what I would like to see even more is something that would let us monitor behavior of a truck, either stock one or modded one, down the freeway (dyno is not real world) so we can say we know everything is OK vs we think we are OK.

ZoranC

#4

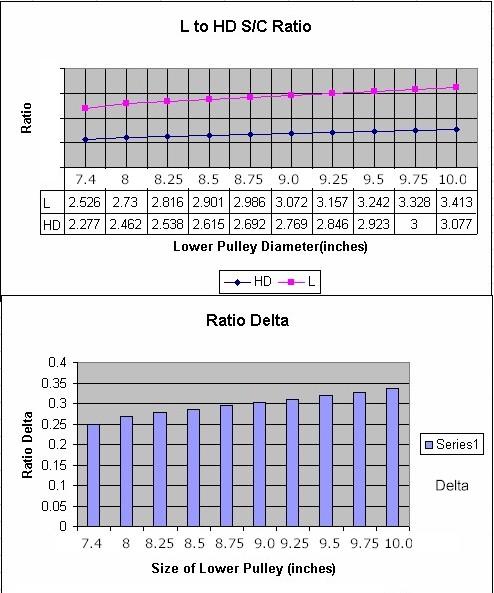

The ratio increase as you increase lower pulley size is NOT linear as you can see from the graph.

The delta between a stock L upper and stock HD upper, with an increasing lower pulley is NOT linear as well. The delta is more directly proportionate as the lower pulley diameter increases.

Your math is correct.

I have long suspected the reality of the 2lbs difference between the L. I just couldn't buy what the tuners we're saying that a 6lb on on HD is the same as a 4lb on the L. This is not meant to bash any of our highly respectable tuners.

The equation holds true at the base point, but no longer holds true as you increase lower pulley diameter. Therefore it will yield the same effect if you decrease the lower pulley diameter.

Take this information with some grain of salt or

I got a headache from all this math.. gotta get some sleep

The delta between a stock L upper and stock HD upper, with an increasing lower pulley is NOT linear as well. The delta is more directly proportionate as the lower pulley diameter increases.

Your math is correct.

I have long suspected the reality of the 2lbs difference between the L. I just couldn't buy what the tuners we're saying that a 6lb on on HD is the same as a 4lb on the L. This is not meant to bash any of our highly respectable tuners.

The equation holds true at the base point, but no longer holds true as you increase lower pulley diameter. Therefore it will yield the same effect if you decrease the lower pulley diameter.

Take this information with some grain of salt or

I got a headache from all this math.. gotta get some sleep

Last edited by chesterc; 01-15-2003 at 02:17 AM.

#5

Re: Pulley size calculations... go w/ me on this one

*And, for those wanting to run a lower pulley with no chip, it is understood that the L will run fine with a 2lb lower and no chip. Using a metco pulley, the ratio would be such that the JL 5lb lower will net slightly more than 2lbs using a metco (8inches) and about 1.9lbs on the JDM 2lb lower (7.8”)*

I was thinking of useing a 5# pulley.......so how much boost does that net me?

I was thinking of useing a 5# pulley.......so how much boost does that net me?

#6

#7

Here are your numbers:

L with: JDM (7.8") Metco (8") (these are supposed to both be 2lbrs

7.8/2.93=2.662 ratio 8/2.93=2.730 ratio

So, to get the same ratio on the HD:

X/3.25=2.662 (JDM) or x/3.25=2.730 (Metco)

Therefore: 8.6515" or 8.7725" to get the same level of boost on a HD that the L gets from the two above pullies.

The 4lb pullies are 8.5" in diameter so they are too small to net 2lbs... The JL 5lb would be 8.75" in O.D. which would net just a fraction over the same amount of boost the Metco 2lb pulley would net on the L.

So, if I was going chipless, I would go 5lbr, get a set of plugs one range colder, gap them down around .38, and then get it dynoed in cold weather to be sure.

Bottom line is you would have a pretty damn fast truck with no chip. No chip means you can go back for warranty work without hassle as long as you drop the pulley before you go in...

*I AM NOT A TUNER*

But, I have known for a while that the numbers didn't add up. I just haven't taken the time to sit down and calculate it. If any of you remember, I was asking about the HD upper size quite some time ago as back then I knew there was a problem with the blanket statement of "2lbs less".

Ratio *changes* are linear when changing the size of one pulley by the same amount in 2 different pairs of pulleys. say a 12/2 and 20/2 now become a 12/4 and a 20/4. Ratios go from 6 and 10 to 3 and 5. Both 50% increase in size in smaller pulley and a 50% decrease in ratio. The *actual ratio* however is not linear because of the different sized pullies...

So, what are the tuners doing for information concerning the amount of fuel, timing, etc.? If my truck is tuned for a 6lb lower, and the assumption is made that it is simply a 4lb tune on an L, I am running WAY rich and nowhere near the amount of timing I could be...

However, those with 8lb lowers are getting a tune very close to what an L would be with a 6lb. That might explain the radical difference in HP and 1/4 times those with 8lb lowers are experiencing over the 6 people like me. Their isn't much left going from 4-6 on the L. Some, but not a 1/2 or more in the 1/4...

Do not tune your truck with my calculations as I am still not 100% sure that 3.25 is *exactly* correct.

What I need is someone that has a precision set of calipers to measure the OD and ID of both the L and the HD pulley and that would give us something better to work with. Even 3 or 4 100ths can make a fair sized difference in ratio, so I would want to know the exact numbers with 1/1000 of an inch.

BTW, Thanks Chester...

L with: JDM (7.8") Metco (8") (these are supposed to both be 2lbrs

7.8/2.93=2.662 ratio 8/2.93=2.730 ratio

So, to get the same ratio on the HD:

X/3.25=2.662 (JDM) or x/3.25=2.730 (Metco)

Therefore: 8.6515" or 8.7725" to get the same level of boost on a HD that the L gets from the two above pullies.

The 4lb pullies are 8.5" in diameter so they are too small to net 2lbs... The JL 5lb would be 8.75" in O.D. which would net just a fraction over the same amount of boost the Metco 2lb pulley would net on the L.

So, if I was going chipless, I would go 5lbr, get a set of plugs one range colder, gap them down around .38, and then get it dynoed in cold weather to be sure.

Bottom line is you would have a pretty damn fast truck with no chip. No chip means you can go back for warranty work without hassle as long as you drop the pulley before you go in...

*I AM NOT A TUNER*

But, I have known for a while that the numbers didn't add up. I just haven't taken the time to sit down and calculate it. If any of you remember, I was asking about the HD upper size quite some time ago as back then I knew there was a problem with the blanket statement of "2lbs less".

Ratio *changes* are linear when changing the size of one pulley by the same amount in 2 different pairs of pulleys. say a 12/2 and 20/2 now become a 12/4 and a 20/4. Ratios go from 6 and 10 to 3 and 5. Both 50% increase in size in smaller pulley and a 50% decrease in ratio. The *actual ratio* however is not linear because of the different sized pullies...

So, what are the tuners doing for information concerning the amount of fuel, timing, etc.? If my truck is tuned for a 6lb lower, and the assumption is made that it is simply a 4lb tune on an L, I am running WAY rich and nowhere near the amount of timing I could be...

However, those with 8lb lowers are getting a tune very close to what an L would be with a 6lb. That might explain the radical difference in HP and 1/4 times those with 8lb lowers are experiencing over the 6 people like me. Their isn't much left going from 4-6 on the L. Some, but not a 1/2 or more in the 1/4...

Do not tune your truck with my calculations as I am still not 100% sure that 3.25 is *exactly* correct.

What I need is someone that has a precision set of calipers to measure the OD and ID of both the L and the HD pulley and that would give us something better to work with. Even 3 or 4 100ths can make a fair sized difference in ratio, so I would want to know the exact numbers with 1/1000 of an inch.

BTW, Thanks Chester...

Last edited by ken800; 01-15-2003 at 10:15 AM.

Trending Topics

#8

My autometer is acting up, so I can't tell you for sure. I can tap it and make a +- 2lbs difference in reading...

I have a helluva lot of mods, too, which might allow me to generate more apparent boost on the gauge but not near that much in actuality.

When I dynoed, one of the things they did was hook up to measure boost. I peaked at 15lbs according to their dyno computer.

However, there is no way mathematically possible that I hit 15lbs...

If I could find some to tap into the casing so I could get *actual* boost pressures, I would do it if I was sure they knew what they were doing...

Ken

I have a helluva lot of mods, too, which might allow me to generate more apparent boost on the gauge but not near that much in actuality.

When I dynoed, one of the things they did was hook up to measure boost. I peaked at 15lbs according to their dyno computer.

However, there is no way mathematically possible that I hit 15lbs...

If I could find some to tap into the casing so I could get *actual* boost pressures, I would do it if I was sure they knew what they were doing...

Ken

#9

One more post and I'll stop and let folks read my rants...

How many of you would be interested in a 7lb lower? I would net just over 4lbs of boost relative to the L. (still 7lbs on HD), but should actually give you the same as an L and a 4lb lower....

I think JL has his made for him by a machine shop. I believe just about every other tuner is selling a 3rd party like metco or something. (obvioulsy JDM makes theirs)

I don't know how many he would need to sell to do it, but I, for one, will take the first assuming I can get my hands on a high precision caliper, and HD, and a Lightning all in one place at one time to confirm all of this math.

Ken

How many of you would be interested in a 7lb lower? I would net just over 4lbs of boost relative to the L. (still 7lbs on HD), but should actually give you the same as an L and a 4lb lower....

I think JL has his made for him by a machine shop. I believe just about every other tuner is selling a 3rd party like metco or something. (obvioulsy JDM makes theirs)

I don't know how many he would need to sell to do it, but I, for one, will take the first assuming I can get my hands on a high precision caliper, and HD, and a Lightning all in one place at one time to confirm all of this math.

Ken

#12

I just posted this formula on NLOC, will post here for your information.

a = lower pulley diameter.

b = upper pulley diameter.

1.84 x ( a / b )

------------------ x 14.7 - 14.7 = BOOST

2.7

Plug in the pulley size you want to run (upper and/or lower) and apply the formula to determine the resulting maximum boost this combination will produce on your engine.

Good luck.

a = lower pulley diameter.

b = upper pulley diameter.

1.84 x ( a / b )

------------------ x 14.7 - 14.7 = BOOST

2.7

Plug in the pulley size you want to run (upper and/or lower) and apply the formula to determine the resulting maximum boost this combination will produce on your engine.

Good luck.

#13

Ken800

A few months ago I attempted to make similar calculations because I also didn't buy the fact that that the L pully gave a reliable indication of HD boost. I went a slightly different route and calculated blower RPM figuring that the blower speed gave me the best indication of boost - if the L was spinning at 14000 with pully x and achieved y boost then to get similar boost on the HD I would need pully that spun the blower at 14000 rpms regardless of the L boost rating. My calculations achieved results similar to yours - I cant be specific since my spreadsheet is at home and I am at work.

I used 14000 rpm because of an old post I found from Sal on the Lightning forum. Sadly the post is from Feb 2000. The post indicated that the blower could only safely be run to 14000 rpms - https://www.f150online.com/forums/sh...hreadid=22122. I can not validate that this information and it is old but I have been unable to find any information otherwise. On the other hand, Sal sells much larger pullies now so there may be different information now available.

Your calculation of being able to use the 5lb pully without a chip also fits with my blower speed calculation comparison with the L. The L with its 2 lb pully is just about the same at the HD with a 5. What is still unknown - at least to me - is whether the HD computer is as flexible as the L computer. A good dyno after install should yeild the info I need about the fuel/air ratios.

Something that Tim Skelton brings up on his L page - http://www.timskelton.com/lightning/index.htm - is that a larger pully might not be a bad idea if a chip was tuned to drop the max engine RPMs. Basically, you get the benefit of a larger area under the curves (HP and TQ) but don't have to worry about overspinning the blower. As far as I have seen no one is doing that yet but it seems like a really good idea.

A few months ago I attempted to make similar calculations because I also didn't buy the fact that that the L pully gave a reliable indication of HD boost. I went a slightly different route and calculated blower RPM figuring that the blower speed gave me the best indication of boost - if the L was spinning at 14000 with pully x and achieved y boost then to get similar boost on the HD I would need pully that spun the blower at 14000 rpms regardless of the L boost rating. My calculations achieved results similar to yours - I cant be specific since my spreadsheet is at home and I am at work.

I used 14000 rpm because of an old post I found from Sal on the Lightning forum. Sadly the post is from Feb 2000. The post indicated that the blower could only safely be run to 14000 rpms - https://www.f150online.com/forums/sh...hreadid=22122. I can not validate that this information and it is old but I have been unable to find any information otherwise. On the other hand, Sal sells much larger pullies now so there may be different information now available.

Your calculation of being able to use the 5lb pully without a chip also fits with my blower speed calculation comparison with the L. The L with its 2 lb pully is just about the same at the HD with a 5. What is still unknown - at least to me - is whether the HD computer is as flexible as the L computer. A good dyno after install should yeild the info I need about the fuel/air ratios.

Something that Tim Skelton brings up on his L page - http://www.timskelton.com/lightning/index.htm - is that a larger pully might not be a bad idea if a chip was tuned to drop the max engine RPMs. Basically, you get the benefit of a larger area under the curves (HP and TQ) but don't have to worry about overspinning the blower. As far as I have seen no one is doing that yet but it seems like a really good idea.

#15

Originally posted by crockett59

Ken800,

Thank you for explaining that......

I was thinking of going with a 5# pulley. So technically speaking I can run up to a 5#er and have NO CHIP.....Right?

Ken800,

Thank you for explaining that......

I was thinking of going with a 5# pulley. So technically speaking I can run up to a 5#er and have NO CHIP.....Right?

Remember I am assuming the 3.25" upper size until I get my hands on a high precision caliper...

I'll try to do that this weekend...

Ken