What does a 30A relay do for an onboard compressor?

#1

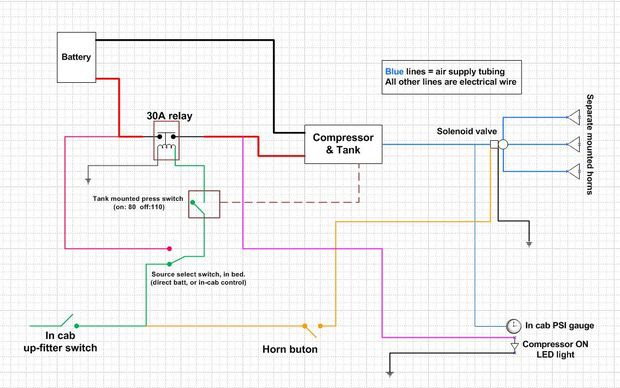

Train Horns Electrical System

I am looking to put train horns in my truck. Can I just wire them the same way I would wire LED lights in the truck or would I have to go off of this diagram?<br/><br/>I don't know how a relay works (yet) but I definitely want to learn. If someone can take the time to seriously explain how this diagram works I would greatly appreciate it. 12V DC

#2

Join Date: Nov 2006

Location: Memphis, TN 38135, USA, Earth

Posts: 5,495

Likes: 0

Received 7 Likes

on

7 Posts

A common automotive relay (and most others) is an electromechanical device that uses a relatively low current (Amperes) to switch a relatively high current on/off (a 4-terminal SPST relay), or between 2 outputs (a 5-terminal SPDT relay, like most in your truck). The trigger side of the relay (the coil) consumes very little power to generate a magnetic field. That field pulls a contact which can carry much more current than the trigger circuit. Find a relay from a truck like yours in the junkyard, pull its cover off, and look inside. Then plug it in (or attach jumper wires to a 12V battery) and watch it work. Think of it as an electrically-operated electric switch. The trigger side is very similar to a solenoid, which is why the terms are often confused - especially in reference to starters. These show starter relays opened up:

.

.

This shows a solenoid:

This shows how Ford set up the optional factory train horns (back in the 70s & early 80s):

The diagram you posted is dangerous because it doesn't indicate fuses anywhere. There should be one between the battery & 30A relay (size depends on the pump's normal current draw at max pressure), and a much-smaller fuse for the upfitter switch (possibly already built-in). This shows how to add fuses to the truck's original fuse blocks so they're easy-to-find later:

That diagram shows the upfitter switch supplying power to the pressure switch AND to the horn switch. So when the dash switch is OFF, the horn won't work even if there's air in the tank. Since the original horn isn't shown, I assume you're intended to leave that circuit alone, and add a new "horn switch" somewhere (on the dash?). Then there's another switch (in the bed?) indicated to bypass the dash switch and keep the air system on constantly. I don't get why, and I don't think it's a very good way to wire up the system (for a lot of reasons).

Assuming your truck HAS a fused upfitter switch, I'd wire that to control the pump pressure switch. It's up to you to decide if it should be hot with the key off - I'm not familiar (yet) with how Ford wires those upfitter switches. That will keep the tank full whenever the upfitter switch is on, and will allow the air horns to work whether the switch is on or off (assuming there's enough air in the tank). Then I'd wire the original horns to the air horn solenoid so that one button controls both.

But if you want to be able to turn the air horns off...

I'd wire the pressure switch so it can keep the tank filled whenever the key is in RUN (no other control on the pump). Then connect a splice from the original horn hot wire to the upfitter, and run that to the air solenoid.

I consider the LED & gauge to be unnecessary distractions - I'd omit them. Same for the bed switch - it's just another potential failure point, with no real benefit.

.

.

This shows a solenoid:

This shows how Ford set up the optional factory train horns (back in the 70s & early 80s):

The diagram you posted is dangerous because it doesn't indicate fuses anywhere. There should be one between the battery & 30A relay (size depends on the pump's normal current draw at max pressure), and a much-smaller fuse for the upfitter switch (possibly already built-in). This shows how to add fuses to the truck's original fuse blocks so they're easy-to-find later:

That diagram shows the upfitter switch supplying power to the pressure switch AND to the horn switch. So when the dash switch is OFF, the horn won't work even if there's air in the tank. Since the original horn isn't shown, I assume you're intended to leave that circuit alone, and add a new "horn switch" somewhere (on the dash?). Then there's another switch (in the bed?) indicated to bypass the dash switch and keep the air system on constantly. I don't get why, and I don't think it's a very good way to wire up the system (for a lot of reasons).

Assuming your truck HAS a fused upfitter switch, I'd wire that to control the pump pressure switch. It's up to you to decide if it should be hot with the key off - I'm not familiar (yet) with how Ford wires those upfitter switches. That will keep the tank full whenever the upfitter switch is on, and will allow the air horns to work whether the switch is on or off (assuming there's enough air in the tank). Then I'd wire the original horns to the air horn solenoid so that one button controls both.

But if you want to be able to turn the air horns off...

I'd wire the pressure switch so it can keep the tank filled whenever the key is in RUN (no other control on the pump). Then connect a splice from the original horn hot wire to the upfitter, and run that to the air solenoid.

I consider the LED & gauge to be unnecessary distractions - I'd omit them. Same for the bed switch - it's just another potential failure point, with no real benefit.

Last edited by Steve83; 08-04-2015 at 08:27 PM.

#3

Alternate System

What if I were to wire the compressor to the battery and add an inline fuse (probably 30A) and then I ran the actual horn solenoid to a simple fuse tap? Now how about instead of having an electric switch for the horns? I'm pretty sure I only need power for the compressor and then I can put the horns on a spring valve the same way the truckers do. Do you know what I would do to bypass that? (If not I will figure it out when I get everything set up. This is usually how it goes anyways.)

#4

What does a 30A relay do for an onboard compressor?

What does a 30A relay do for an onboard air compressor? I am not familiar with relays so I am thinking about running the compressor to the battery and using a 30A inline fuse to a switch which will turn the compressor on/off. Now I know the compressor is supposed to automatically turn on/off when the tank becomes low/full air PSI. My guess is the relay tells the compressor to turn on/off at these times. Is this true and do I need the relay for the compressor to know when to turn on/off. Please explain what the relay is and does. I looked it up but don't really understand it. Thanks.

#6

Join Date: Oct 2002

Location: St. Louis (Out in the woods)

Posts: 7,247

Likes: 0

Received 104 Likes

on

97 Posts

If your switch's contacts are RATED for 30 amps, it will work. Same for a relay, which is basically a switch that can handle a lot of current while only requiring a small amount of current to activate it. Of course, you also have to ensure the COMPLETE circuit (wiring, fuse, etc) are all sized correctly for the anticipated load.

#7

Trending Topics

#8

Join Date: Jun 2002

Location: Under the flightpath of old ORD 22R

Posts: 10,511

Likes: 0

Received 7 Likes

on

7 Posts

As posted above, if the switch is rated for the draw on the compressor, it will work the same as the relay.

I would be more concerned about the current inrush when the compressor switch is turned on and arcing in the switch contacts as to if it will work long term even with the correctly sized switch.

If the compressor is rated at 30 A ( or 26A and fused at 30 A ) I would over size the relay to at least 40 A, as well as the fuse holder ( not the fuse itself ).

Use a screw terminal MAXI or AMI/MIDI fuse holder and the correct size fuse.

Next the wiring. 10 AWG wire is what is used for up to 30' for 30 A.

This is where the relay will be useful, if you are trying to get 2 10 AWG wires to the switch location and mounting a 30A switch, it is not going to be a fun job and limit your switch options and maybe mounting locations.

These are long term operations items, not day one install things to keep in mind.

I would be more concerned about the current inrush when the compressor switch is turned on and arcing in the switch contacts as to if it will work long term even with the correctly sized switch.

If the compressor is rated at 30 A ( or 26A and fused at 30 A ) I would over size the relay to at least 40 A, as well as the fuse holder ( not the fuse itself ).

Use a screw terminal MAXI or AMI/MIDI fuse holder and the correct size fuse.

Next the wiring. 10 AWG wire is what is used for up to 30' for 30 A.

This is where the relay will be useful, if you are trying to get 2 10 AWG wires to the switch location and mounting a 30A switch, it is not going to be a fun job and limit your switch options and maybe mounting locations.

These are long term operations items, not day one install things to keep in mind.

#10

Join Date: Nov 2006

Location: Memphis, TN 38135, USA, Earth

Posts: 5,495

Likes: 0

Received 7 Likes

on

7 Posts

Originally Posted by CKAL

What if I were to wire the compressor to the battery and add an inline fuse (probably 30A)...

Yes, you could hook the compressor to the battery (via a fuse), but if the system ever leaked, the compressor would run until the battery was dead. A switch (or relay) is wise.

Yes, you could use a manual valve instead of a solenoid, but that would require more holes in the body for air lines to run in & out of the cab, giving your more potential for leaks (both air AND rain).

Last edited by Steve83; 08-05-2015 at 10:23 AM.