F150 Rear Seat Removal 2004-2008 - MY WAY

#1

F150 Rear Seat Removal 2004-2008 - MY WAY

Yes, this is ANOTHER article about how to remove the backrest from the rear wall of the 2004-2008 F150 (Super Cab or SuperCrew).

I am about to begin a full blown audio system instillation and need to gain access to my rear wall in order to mount my amplifiers.

You may ask why...why another one? For a couple of reasons:

1. Because this backrest is (seemingly) a real PAIN IN THE AXX.

2. Because I downloaded and printed three different articles during my initial attempt to remove my backrest and NONE of them were very clear. Dont get me wrong, their information was accurate, but each of them was either more difficult than necessary or not articulate enough for my taste.

First of all let me say this is its frankly VERY easy to remove the backrest. Oh sure, it is not as easy as a factory folding seat (that we all wish we had) but its not as bacd as it seems. Trust me, I know because I spent almost 90 minutes following the other install articles and got NO where other than getting the two bolts off the seatbelt tower. I never got the backrest to budge even a fraction of an inch.

So I gave up and went to my computer. I did find an article by Mitchell Repair systems that seemed to have information in it that is directly from Ford. After reading this, suddenly the light bulb went off and I went back outside and attempted the removal. In thirty seconds the seat was off!!

From start to finish, this backrest removal can be done in 5-10 minutes. If not, you are doing something wrong. And, despite some REALLY strenuous effort the first time, the second time, it took no effort at all.

Without further adeu....here is my attempt at a more articulate and clear method of removing the backrest.

I am about to begin a full blown audio system instillation and need to gain access to my rear wall in order to mount my amplifiers.

You may ask why...why another one? For a couple of reasons:

1. Because this backrest is (seemingly) a real PAIN IN THE AXX.

2. Because I downloaded and printed three different articles during my initial attempt to remove my backrest and NONE of them were very clear. Dont get me wrong, their information was accurate, but each of them was either more difficult than necessary or not articulate enough for my taste.

First of all let me say this is its frankly VERY easy to remove the backrest. Oh sure, it is not as easy as a factory folding seat (that we all wish we had) but its not as bacd as it seems. Trust me, I know because I spent almost 90 minutes following the other install articles and got NO where other than getting the two bolts off the seatbelt tower. I never got the backrest to budge even a fraction of an inch.

So I gave up and went to my computer. I did find an article by Mitchell Repair systems that seemed to have information in it that is directly from Ford. After reading this, suddenly the light bulb went off and I went back outside and attempted the removal. In thirty seconds the seat was off!!

From start to finish, this backrest removal can be done in 5-10 minutes. If not, you are doing something wrong. And, despite some REALLY strenuous effort the first time, the second time, it took no effort at all.

Without further adeu....here is my attempt at a more articulate and clear method of removing the backrest.

Last edited by ARCuhTEK; 02-13-2009 at 08:02 PM.

#2

To further paraphrase this entire backrest removal:

1. Just remove the top of the seat belt tower. It is very obvious what you have to do once you are looking at it.

2. Stick a screw driver beside one of the two latches (see photo) and aim toward the roof. Push forward. Your screw driver will slide in the access hole (it may take you a couple of tries). Once you feel the screw driver stop, push hard. At the same time take your free arm and push the seat down (not very much effort is required) Keep pushing the screw driver,....yo will feel a liitle movement. When you feel the movement, quickly grab the bottom of the seat and lift up. One side is done!

Repeat.

After wasting 90 minutes when it really only took 5 mins....I was somewhere between embarrassed and angry. So I wrote this artilce to save YOU time.

Good luck!

1. Just remove the top of the seat belt tower. It is very obvious what you have to do once you are looking at it.

2. Stick a screw driver beside one of the two latches (see photo) and aim toward the roof. Push forward. Your screw driver will slide in the access hole (it may take you a couple of tries). Once you feel the screw driver stop, push hard. At the same time take your free arm and push the seat down (not very much effort is required) Keep pushing the screw driver,....yo will feel a liitle movement. When you feel the movement, quickly grab the bottom of the seat and lift up. One side is done!

Repeat.

After wasting 90 minutes when it really only took 5 mins....I was somewhere between embarrassed and angry. So I wrote this artilce to save YOU time.

Good luck!

#5

It took me all of 30 seconds to get it off. The screwdriver method does work well, but i found it easier to just mash my arm back behind the seat around the lower side of it, and pull the clip with my finger and pop the seat out.

One thing you should add to your post: ZIP TIE THE CLIPS ONCE YOU GET THE SEAT OFF. That way, all you have to do the next time is take the 2 nuts off and pull the seat right off.

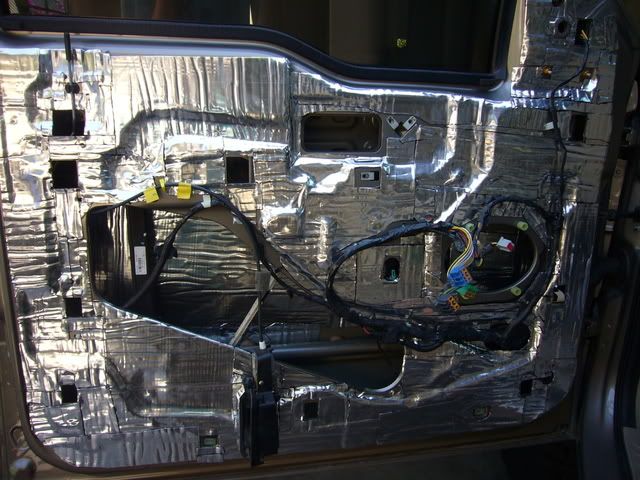

Look at the lower right of my picture, you can see where i zip tied the clips:

One thing you should add to your post: ZIP TIE THE CLIPS ONCE YOU GET THE SEAT OFF. That way, all you have to do the next time is take the 2 nuts off and pull the seat right off.

Look at the lower right of my picture, you can see where i zip tied the clips:

#6

I have no idea how you got your arms behind the backrest. I did, but not without a lot of strain and effort. Once to got my hand on the slip, I found that I had no range of motion left in order to even attempt to free the clip (even when pushing down on the seat..etc.).

#7

Nice photo of your install. Now that I have seen my own truck stripped, I can more easily tell what you have done.

It looks like you also have the window motor. Is there any chance that the motor can be relocated, even slightly?

I have a total of three amps to mount, plus a sound processor, plus positive and ground distribution blocks and of course, the MDF board itself.

Did you use 1/2" or 3/4" thick MDF? It appears you used 3/4" I think most amps are approx. the same height. I know all three of mine (from different mfr.s) are within 1/16" in height. SO that is good. From your photo, it appears you have plenty of room between the amp and the backside of the backrest. Well at least more than I expected.

One more thing: Did you cut out areas on the MDF board to allow air passage to the rear vents at each side of the rear wall? I can see an open area on the drivers side, but not sure on your passenger side. I had no idea these vents were on thye rear wall until tonight.

It looks like you also have the window motor. Is there any chance that the motor can be relocated, even slightly?

I have a total of three amps to mount, plus a sound processor, plus positive and ground distribution blocks and of course, the MDF board itself.

Did you use 1/2" or 3/4" thick MDF? It appears you used 3/4" I think most amps are approx. the same height. I know all three of mine (from different mfr.s) are within 1/16" in height. SO that is good. From your photo, it appears you have plenty of room between the amp and the backside of the backrest. Well at least more than I expected.

One more thing: Did you cut out areas on the MDF board to allow air passage to the rear vents at each side of the rear wall? I can see an open area on the drivers side, but not sure on your passenger side. I had no idea these vents were on thye rear wall until tonight.

Last edited by ARCuhTEK; 01-18-2009 at 01:15 AM.

Trending Topics

#8

Nice photo of your install. Now that I have seen my own truck stripped, I can more easily tell what you have done.

It looks like you also have the window motor. Is there any chance that the motor can be relocated, even slightly?

I have a total of three amps to mount, plus a sound processor, plus positive and ground distribution blocks and of course, the MDF board itself.

Did you use 1/2" or 3/4" thick MDF? It appears you used 3/4" I think most amps are approx. the same height. I know all three of mine (from different mfr.s) are within 1/16" in height. SO that is good. From your photo, it appears you have plenty of room between the amp and the backside of the backrest. Well at least more than I expected.

One more thing: Did you cut out areas on the MDF board to allow air passage to the rear vents at each side of the rear wall? I can see an open area on the drivers side, but not sure on your passenger side. I had no idea these vents were on thye rear wall until tonight.

It looks like you also have the window motor. Is there any chance that the motor can be relocated, even slightly?

I have a total of three amps to mount, plus a sound processor, plus positive and ground distribution blocks and of course, the MDF board itself.

Did you use 1/2" or 3/4" thick MDF? It appears you used 3/4" I think most amps are approx. the same height. I know all three of mine (from different mfr.s) are within 1/16" in height. SO that is good. From your photo, it appears you have plenty of room between the amp and the backside of the backrest. Well at least more than I expected.

One more thing: Did you cut out areas on the MDF board to allow air passage to the rear vents at each side of the rear wall? I can see an open area on the drivers side, but not sure on your passenger side. I had no idea these vents were on thye rear wall until tonight.

2) That picture was taken a while ago, i currently have 3 amps plus 2 distro blocks in there. Luckily my HU can do al the processing and time alignment I need. 2 amps + distros on the left side, and that single amp on the right. The window motor cannot be relocated, so i worked with what I could, and mounted the amps in directions that they would all fit. Capable of 1800 RMS+ at full tilt.

3) 3/4" MDF. No problem fitting the amps, and I like it loud so i tend to really crank it, yet never have had a problem with overheating.

4) I closed up the vent on the passenger side (covered with 2 layers duct tape then 3 layers of sound deadener). I'm going to do the driver's side soon too. It reduces noise A TON. Reduces exhaust and tire noise big time. I have 35" mud terrains and a 9" Borla muffler and the interior sounds nearly stock on the highway cruising @ 70mph. Slap 1800 watts ontop of that and its SEXY!

The rear vent:

Doors:

rear wall:

Last edited by mSaLL150; 01-18-2009 at 05:24 AM.

#9

#10

Thanks. I have three amps, distribution blocks and a signal processor. I do not have crossovers. It will be tight. I am pretty ****, so I can envision me taking my sweet time on the amp board, wiring pathways etc. I am thinking about mounting my amp board with "feet" or pegs on the rear side, perhaps using small blocks of 1/2" or 3/4" MDF. This woudl allow me to do wiring on the back side and just penetrate to the front side when necessary. Makes for a really clean install. But its tough to get too picky when no one will ever see it. I am more about being organized than anything. I hate opening things up and seeing a plate of spaghetti.

I will be making my chip board template for the amp board today.

Since I am trying to mock up my amp board, I am thinking about getting some 1/2", 3/4" or 1" rigid board (blue board) insulation and mocking it up, including some rudementary blocks representing my amps. Tape it to the wall, put the seat back (release clamps zip tied) and then sitting on the seat, jumping up and down...etc. Remove the backrest and see if there are any impressions or other damage in the blue board. This would give me an idea of how tight it is....since you really cannot see what is going on back there when you put the back rest back on.

I will be making my chip board template for the amp board today.

Since I am trying to mock up my amp board, I am thinking about getting some 1/2", 3/4" or 1" rigid board (blue board) insulation and mocking it up, including some rudementary blocks representing my amps. Tape it to the wall, put the seat back (release clamps zip tied) and then sitting on the seat, jumping up and down...etc. Remove the backrest and see if there are any impressions or other damage in the blue board. This would give me an idea of how tight it is....since you really cannot see what is going on back there when you put the back rest back on.

#11

#12

#13

There are other good mats out there like Damplifier Pro or Dynamat Extreme. I do have some D-pro in my truck too (in the doors). Its just a lot more expensive and a bit thicker. I also have the speaker tweaker pads from second skin. The Raamat gives you a ton more for the money and its just as easy to install and works well.

Check out www.sounddeadenershowdown.com and read up a bit.

The kitchen knife was used to cut some string that i used to measure lengths of wire runs.

PS ARC i no longer have crossovers.

Last edited by mSaLL150; 01-18-2009 at 03:26 PM.

#14

Read this thread, got all excited, figured I was going to finally install that nice rear seat cover I bought for the hound. First step took all of a minute. Fast forward 45 minutes, many cuss words later, and I am no further. Tried the screwdriver method, as well as the jam my fat hand behind the seat method, all with no luck. What the hell could I possibly be doing wrong?