The 77 F-200 Sled puller build...

#1

The 77 F-200 Sled puller build...

I call it the F-200 cause its part 1/2 ton and part 3/4 ton...I plan to do some custom F-200 badges on it after I get the body fixed a little and painted...I really want to put a step side bed on it cause my bed is shot...It is going to be painted flat black cause it hides all the imperfections...

This is my 77 Ford F-150 that I traded a lowered early 90's 2wd Chevy for. I won't have the diesel truck ready any time soon so I want to pull the F-150 here locally. The truck has a 390 (460 setting on shop floor for after the 390 goes). The 390 in it is a great engine and runs strong and dosen't smoke but it is still a 390, I may swap a cam, newer ignition and a 4 barrel intake onto it for a little more power but its still not a 460. It needs some work cause all of the previous owners have cobbled it together and everything failed on me at once. It has a stockish type clutch, NP435 4 speed, 205 case, 3.55 geared full float Dana 60 8 lug in the rear (previous owner's doing and will break at some point) and coil sprung 5 lug Dana 44 high pinion in the front. It has 15x10 steel wheels (5 lug front, 8 lug rear) and it came with brand new 35x12.50x15 B.F. Goodrich A/T's. It has a 5 inch lift kit on it but all they used was 7* C-bushings and 5 inch springs and I plan to swap to drop brackets and less degreed bushings so I can run the radius arms flatter in the future. The rules down here are pretty simple...Gas, 6000 to 7000 pounds, 26 inch hitch, 1 ton drivetrain. Thats it...

Truck...

We took the bed off today and pulled the craptastic hitch some idiot built off it so I can build a good one. I will be sliding the new hitch as far forward as I can. Pics of the new hitch to come later...

Now here somes the not so intelligent part of my build. We decided to chain the truck to a big tree in the back yard and put a load on it too see if it would wheel hop bad with no bars, the engine wouldn't bog down or misfire. It pulled all 4 tires hard and the clutch held. Then on the third try the truck did a 4 wheel jump into the air and the rear yoke gave up the ghost and got the driveshaft...

Yoke...

Shaft...

After we pulled it out and looked at it we realized it was just a ticking time bomb and with a little hard driving on the street it would of let go. The yokes were touching from the driveshaft angles. I picked up a 2 piece Super Duty 1410 u-joint driveshaft from Midway Auto Salvage and had it cut and welded to make a single shaft with a slip spline in it by Central Florida Driveshaft here in Lakeland. I ordered a 1410 u-bolt yoke for both my 60 and my 205 from Jess at High Angle Driveline so I can run the SD shaft. This cured the touching yokes problem. I ordered all my suspension tabs from Ballistic Fabrication except the front mounts for my traction bars. I am using 2.5 inch wide front spring hangers from a F-53 motorhome chassis that I have in the back yard with the bolt holes drilled out to 1 inch...

New shaft...

Spring hangers from the motorhome. I got these off the frame and drilled for 1 inch bolts and ready to weld to the frame...

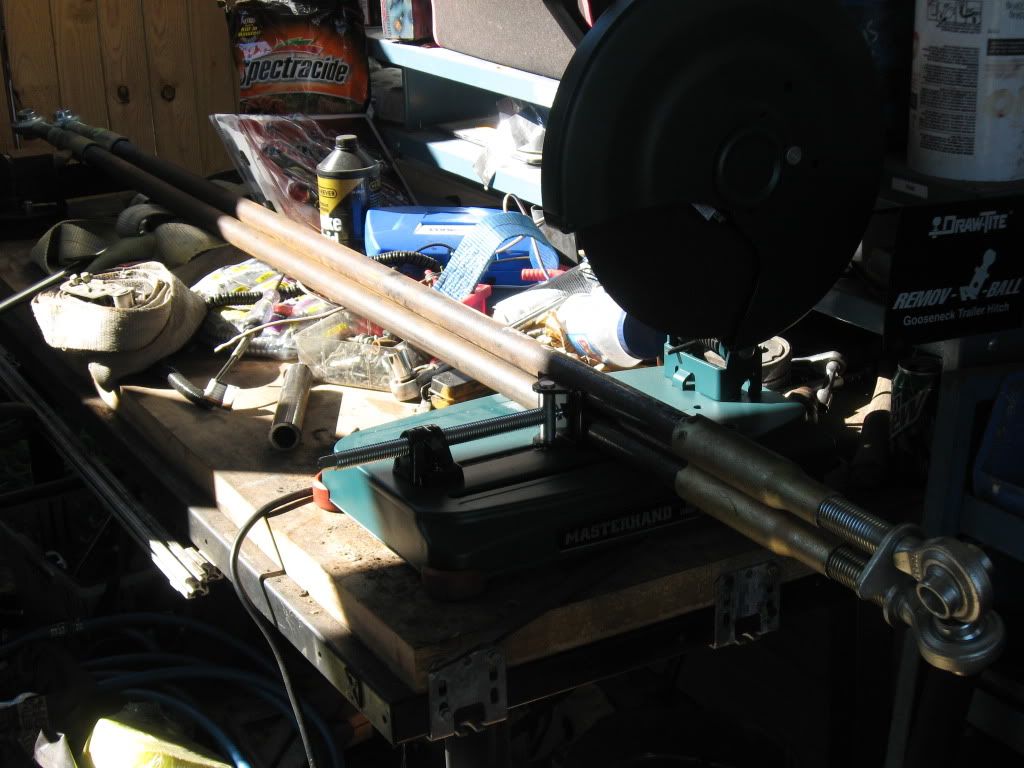

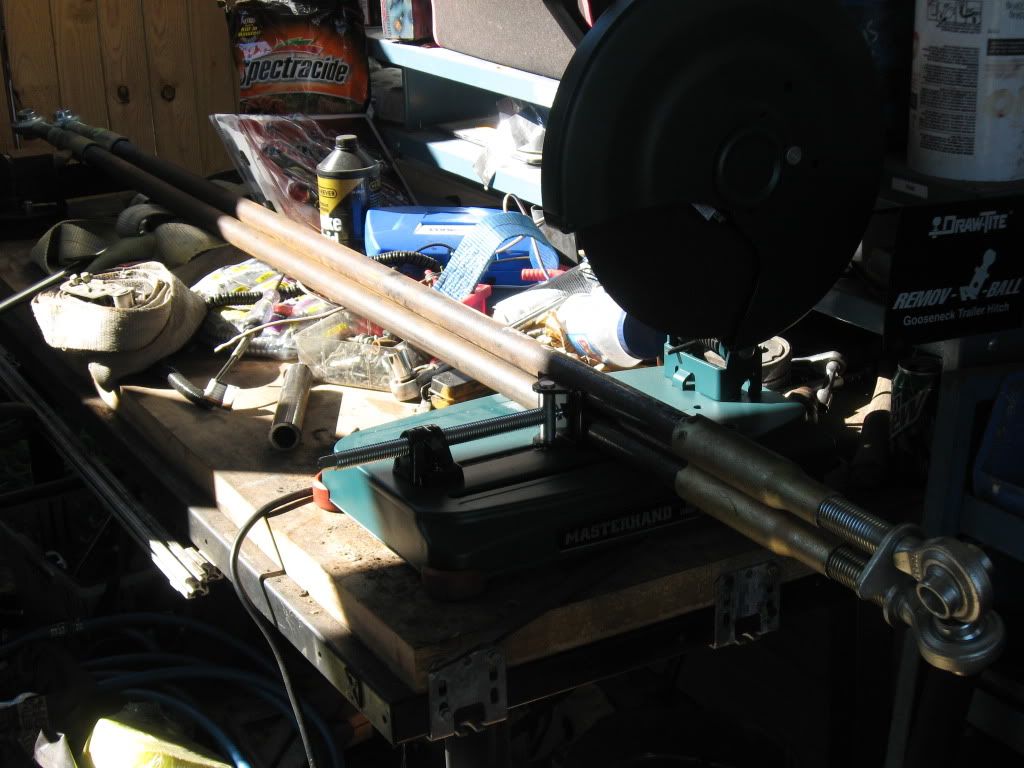

I bought two Category 2 tractor top links for traction bars and four Category 1 links to lock my suspension from Tractor Supply Company. I took the Cat. 2's and cut them and I am sleeving them inside with 1 inch Schedule 40 and plug welding them and sleeved the outside with 2x2 inch 11 gauge box tubing (No one sold round tubing that would fit over it here in Lakeland) that will be welded plus being plug welded. I got all my steel from "Piece Of Metal" which is Samson Metal's shop here in Lakeland that sells "cut off" pieces of steel, aluminum and other metal that the main shop dosen't use. So much nicer than having to buy 21 foot sticks of steel...

Links...

I built a new hitch from a cross piece from a Reese hitch and welded it to 2 pieces of 18 inch long 1/4 inch thick 3x3 angle iron and bolted it to the frame with ten 1/2 inch bolts and two 5/8 grade 8 bolts. I slid back several inches from the stock location. I may do some more bracing to make sure it won't fail. I also need to build some sled bump stops this week so if something break (pinion or axle shaft I'm sure) the sled won't hit me in the ***. I will be posting some pics of the hitch if I get a chance to take some today...

Here is the rearend all welded solid into place and some shots of our removable lower driveshaft loop I built with some hitch tube and 8 inch diameter by 3 inch long Schedule 40. We drilled a hole in the top piece of matching Scedule 40 and bolted it to the main cab crossmember and put 2 tack welds on it so it wouldn't turn. Don't worry, the top shield is temporary, I will be building a complete removable driveshaft loop setup with the two 3 inch u-joint shields and two 2 inch pieces of 8 inch schedule 40 all welded and bolted together. Ignore the chicken-chit welds. We were having welder problems but they are burned in and holding. I already got plans for the new lower tabs for when I have to put a bigger rearend under the truck so it will look and work better, this rear will be replaced by one of my 14 bolts, Dana 70's or a 10.25 Ford. I may go with the 10.25 cause it will bolt right in with no modifications...When I get a chance I will be welding some 4 inch angle iron to the sides of the frame (with proper bracing of course) and drilling a hole in it so I can use a piece of all-thread to build bump stops so if the rules say I have to have moving suspension I will remove my 4 locating links and adjust the all-thread down so it only has the minimal required travel...Oh and don't worry about the brake lines, I am running all new this week...

We worked four 18 hour days to get it ready for the pull today and the mechanical fuel pump and ignition box fails before we get it unloaded at the pull after driving 1 1/2 hours to get there...Oh well. We won't have anymore problems because all of these problems will be eliminated...

This thing is not the best built by no means but this is the first complete pulling truck that I have built from scratch, I have helped build several but never one of my own So I took what I have learned over the years and applied it to this truck, plus I learned alot of stuff and when I build my diesel truck it will be a much better built truck. This truck will be changed around a little after looking and working on it but for now, it will "work" for now...

This is my 77 Ford F-150 that I traded a lowered early 90's 2wd Chevy for. I won't have the diesel truck ready any time soon so I want to pull the F-150 here locally. The truck has a 390 (460 setting on shop floor for after the 390 goes). The 390 in it is a great engine and runs strong and dosen't smoke but it is still a 390, I may swap a cam, newer ignition and a 4 barrel intake onto it for a little more power but its still not a 460. It needs some work cause all of the previous owners have cobbled it together and everything failed on me at once. It has a stockish type clutch, NP435 4 speed, 205 case, 3.55 geared full float Dana 60 8 lug in the rear (previous owner's doing and will break at some point) and coil sprung 5 lug Dana 44 high pinion in the front. It has 15x10 steel wheels (5 lug front, 8 lug rear) and it came with brand new 35x12.50x15 B.F. Goodrich A/T's. It has a 5 inch lift kit on it but all they used was 7* C-bushings and 5 inch springs and I plan to swap to drop brackets and less degreed bushings so I can run the radius arms flatter in the future. The rules down here are pretty simple...Gas, 6000 to 7000 pounds, 26 inch hitch, 1 ton drivetrain. Thats it...

Truck...

We took the bed off today and pulled the craptastic hitch some idiot built off it so I can build a good one. I will be sliding the new hitch as far forward as I can. Pics of the new hitch to come later...

Now here somes the not so intelligent part of my build. We decided to chain the truck to a big tree in the back yard and put a load on it too see if it would wheel hop bad with no bars, the engine wouldn't bog down or misfire. It pulled all 4 tires hard and the clutch held. Then on the third try the truck did a 4 wheel jump into the air and the rear yoke gave up the ghost and got the driveshaft...

Yoke...

Shaft...

After we pulled it out and looked at it we realized it was just a ticking time bomb and with a little hard driving on the street it would of let go. The yokes were touching from the driveshaft angles. I picked up a 2 piece Super Duty 1410 u-joint driveshaft from Midway Auto Salvage and had it cut and welded to make a single shaft with a slip spline in it by Central Florida Driveshaft here in Lakeland. I ordered a 1410 u-bolt yoke for both my 60 and my 205 from Jess at High Angle Driveline so I can run the SD shaft. This cured the touching yokes problem. I ordered all my suspension tabs from Ballistic Fabrication except the front mounts for my traction bars. I am using 2.5 inch wide front spring hangers from a F-53 motorhome chassis that I have in the back yard with the bolt holes drilled out to 1 inch...

New shaft...

Spring hangers from the motorhome. I got these off the frame and drilled for 1 inch bolts and ready to weld to the frame...

I bought two Category 2 tractor top links for traction bars and four Category 1 links to lock my suspension from Tractor Supply Company. I took the Cat. 2's and cut them and I am sleeving them inside with 1 inch Schedule 40 and plug welding them and sleeved the outside with 2x2 inch 11 gauge box tubing (No one sold round tubing that would fit over it here in Lakeland) that will be welded plus being plug welded. I got all my steel from "Piece Of Metal" which is Samson Metal's shop here in Lakeland that sells "cut off" pieces of steel, aluminum and other metal that the main shop dosen't use. So much nicer than having to buy 21 foot sticks of steel...

Links...

I built a new hitch from a cross piece from a Reese hitch and welded it to 2 pieces of 18 inch long 1/4 inch thick 3x3 angle iron and bolted it to the frame with ten 1/2 inch bolts and two 5/8 grade 8 bolts. I slid back several inches from the stock location. I may do some more bracing to make sure it won't fail. I also need to build some sled bump stops this week so if something break (pinion or axle shaft I'm sure) the sled won't hit me in the ***. I will be posting some pics of the hitch if I get a chance to take some today...

Here is the rearend all welded solid into place and some shots of our removable lower driveshaft loop I built with some hitch tube and 8 inch diameter by 3 inch long Schedule 40. We drilled a hole in the top piece of matching Scedule 40 and bolted it to the main cab crossmember and put 2 tack welds on it so it wouldn't turn. Don't worry, the top shield is temporary, I will be building a complete removable driveshaft loop setup with the two 3 inch u-joint shields and two 2 inch pieces of 8 inch schedule 40 all welded and bolted together. Ignore the chicken-chit welds. We were having welder problems but they are burned in and holding. I already got plans for the new lower tabs for when I have to put a bigger rearend under the truck so it will look and work better, this rear will be replaced by one of my 14 bolts, Dana 70's or a 10.25 Ford. I may go with the 10.25 cause it will bolt right in with no modifications...When I get a chance I will be welding some 4 inch angle iron to the sides of the frame (with proper bracing of course) and drilling a hole in it so I can use a piece of all-thread to build bump stops so if the rules say I have to have moving suspension I will remove my 4 locating links and adjust the all-thread down so it only has the minimal required travel...Oh and don't worry about the brake lines, I am running all new this week...

We worked four 18 hour days to get it ready for the pull today and the mechanical fuel pump and ignition box fails before we get it unloaded at the pull after driving 1 1/2 hours to get there...Oh well. We won't have anymore problems because all of these problems will be eliminated...

This thing is not the best built by no means but this is the first complete pulling truck that I have built from scratch, I have helped build several but never one of my own So I took what I have learned over the years and applied it to this truck, plus I learned alot of stuff and when I build my diesel truck it will be a much better built truck. This truck will be changed around a little after looking and working on it but for now, it will "work" for now...

#7

Alot of of the steel wheel companies sell them...The biggest thing is they want to keep the ears/caps from flying out and hitting the crowd but it will atleast slow down the shaft if it spins out for some reason...I got more loops to put in and some more stuff to do to it but I will be in Ohio for two weeks and I will work more on it when I get back...Sorry about the photo's guys, I exceeded my limit on Photobucket, it will be back up day after tomorrow...