2003 Expedition 4R70W line pressures / NO forward / ONLY reverse

#1

2003 Expedition 4R70W line pressures / NO forward / ONLY reverse

So, this is actually in regard to the transmission I've already replaced. I bought a used transmission from a salvage yard w/ 88k miles supposedly. I installed it, filled it, and went for a short test drive. Whenever I engaged drive, it was delayed which can mean the clutch pack isn't doing so well or pressure is low. Anyhow, when driving around a few blocks, I lost all forward gears. Reverse still worked. The wife towed me back with another vehicle and pushed it into the garage. I bought a line pressure tester and when it finally arrived I tested it throughout the gear range and this is what I got:

P - 50 PSI then drops to 40 after cycling through the gears

R - 110 PSI

N - 40 PSI

D - 70 PSI

2 - 70 PSI

1 - 70 PSI

According to one thing I found on google, all those pressures are good. The manual says it should be 50-65 P, N, D, 2 and 70-100 in R, 1. Calling the dealer and getting numbers from him, he was showing all gears at idle should be 80-100 PSI. That would mean that all pressures are low except reverse which would be high and that doesn't make sense. The ATSG says they are good except P, N(All gears except reverse should be 50-75 PSI and reverse should be 80-120 PSI)

Anyone have an idea what the issue could be?

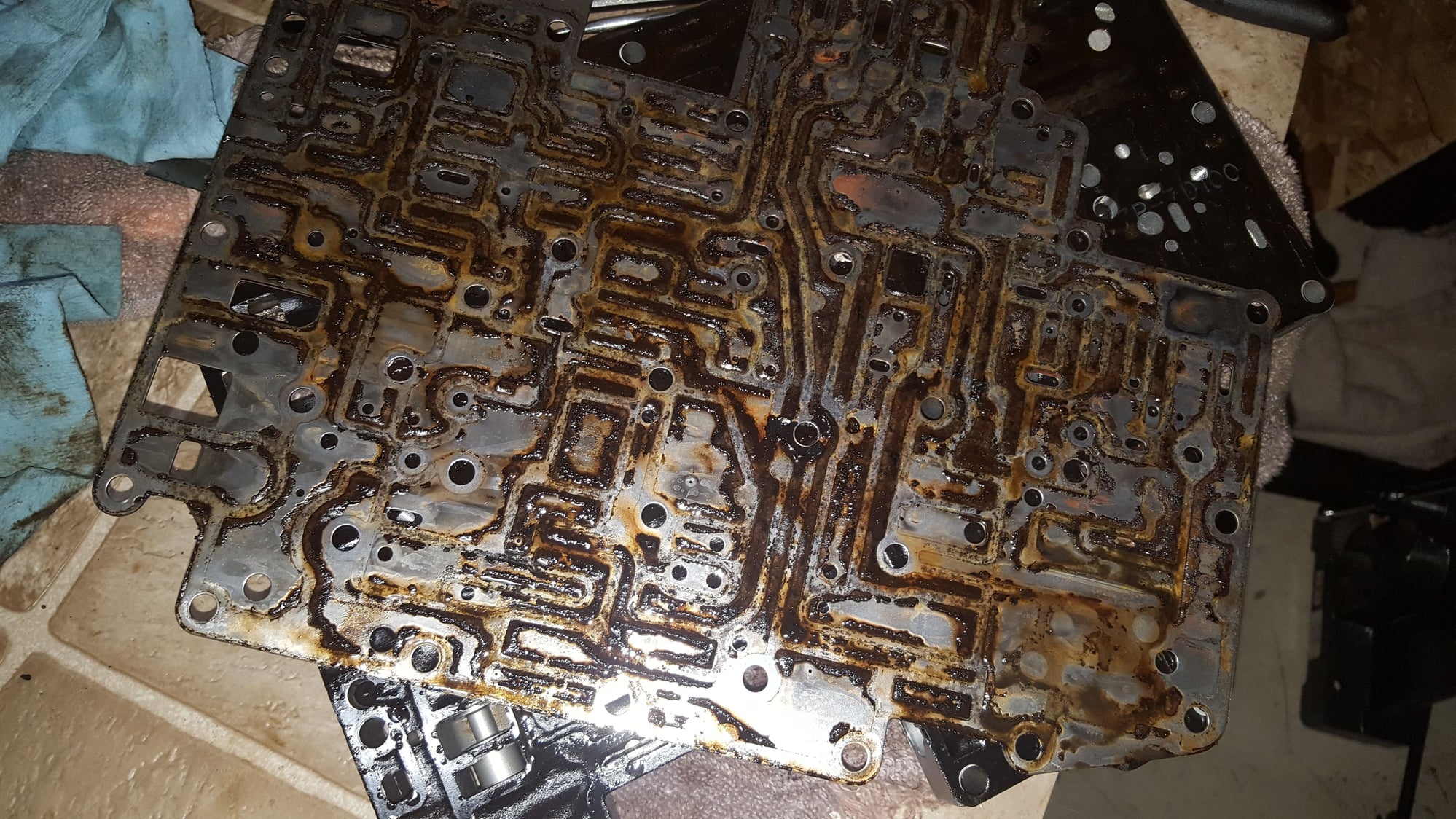

After some reconsideration, I'm wanting to rebuild the old transmission that came out. The only problem it had was after awhile of driving it, I sometimes lost forward gears but M2 worked and after sitting awhile it would be fine again. It also made a grinding noise when in gear (It may have been anytime the engine was running, I don't recall now and I should have taken a video or something) since before this problem started, but has progressively gotten louder. I've already disassembled the transmission and it's actually in good condition which is why I want to return the used transmission I bought and just rebuild this. There were no metal chunks in the pan, but there was more than I would have liked for the other material that accumulates there. Also it looks like a good amount of the material was caked onto the bottom of the valve body, but a minute amount in the actual passage ways. I'm guessing that's all from the frictions? Upon looking at the clutch packs, the forward CP is burned some and some of the frictions are fairly worn (I can post pictures later).

P - 50 PSI then drops to 40 after cycling through the gears

R - 110 PSI

N - 40 PSI

D - 70 PSI

2 - 70 PSI

1 - 70 PSI

According to one thing I found on google, all those pressures are good. The manual says it should be 50-65 P, N, D, 2 and 70-100 in R, 1. Calling the dealer and getting numbers from him, he was showing all gears at idle should be 80-100 PSI. That would mean that all pressures are low except reverse which would be high and that doesn't make sense. The ATSG says they are good except P, N(All gears except reverse should be 50-75 PSI and reverse should be 80-120 PSI)

Anyone have an idea what the issue could be?

After some reconsideration, I'm wanting to rebuild the old transmission that came out. The only problem it had was after awhile of driving it, I sometimes lost forward gears but M2 worked and after sitting awhile it would be fine again. It also made a grinding noise when in gear (It may have been anytime the engine was running, I don't recall now and I should have taken a video or something) since before this problem started, but has progressively gotten louder. I've already disassembled the transmission and it's actually in good condition which is why I want to return the used transmission I bought and just rebuild this. There were no metal chunks in the pan, but there was more than I would have liked for the other material that accumulates there. Also it looks like a good amount of the material was caked onto the bottom of the valve body, but a minute amount in the actual passage ways. I'm guessing that's all from the frictions? Upon looking at the clutch packs, the forward CP is burned some and some of the frictions are fairly worn (I can post pictures later).

#3

The torque converter was replaced. The used one included it. The cooler I didn't, but I did flush it with the stuff in a can. The lines were clean and no blockage was noticed. I forgot to mention the grinding noise wasn't present so there was a problem with the old transmission. Maybe a bearing or something even though they all seemed fine. I also checked the fluid level when I got it towed back while the engine was still running and it was spot on.

I'm leaning towards just rebuilding the old one and changing it back out for longevity. If I was getting a delayed engage in drive and now this, even if I do find something wrong in the valve body or somewhere that I don't have to pull the tranny out, is it really going to last?

What do you think?

I'm leaning towards just rebuilding the old one and changing it back out for longevity. If I was getting a delayed engage in drive and now this, even if I do find something wrong in the valve body or somewhere that I don't have to pull the tranny out, is it really going to last?

What do you think?

Last edited by MetalDrgn; 12-23-2017 at 01:18 PM.

#7

Hah, funny thing is when I bought it, the previous owner hooked a coolant line to the transmission vent tube!

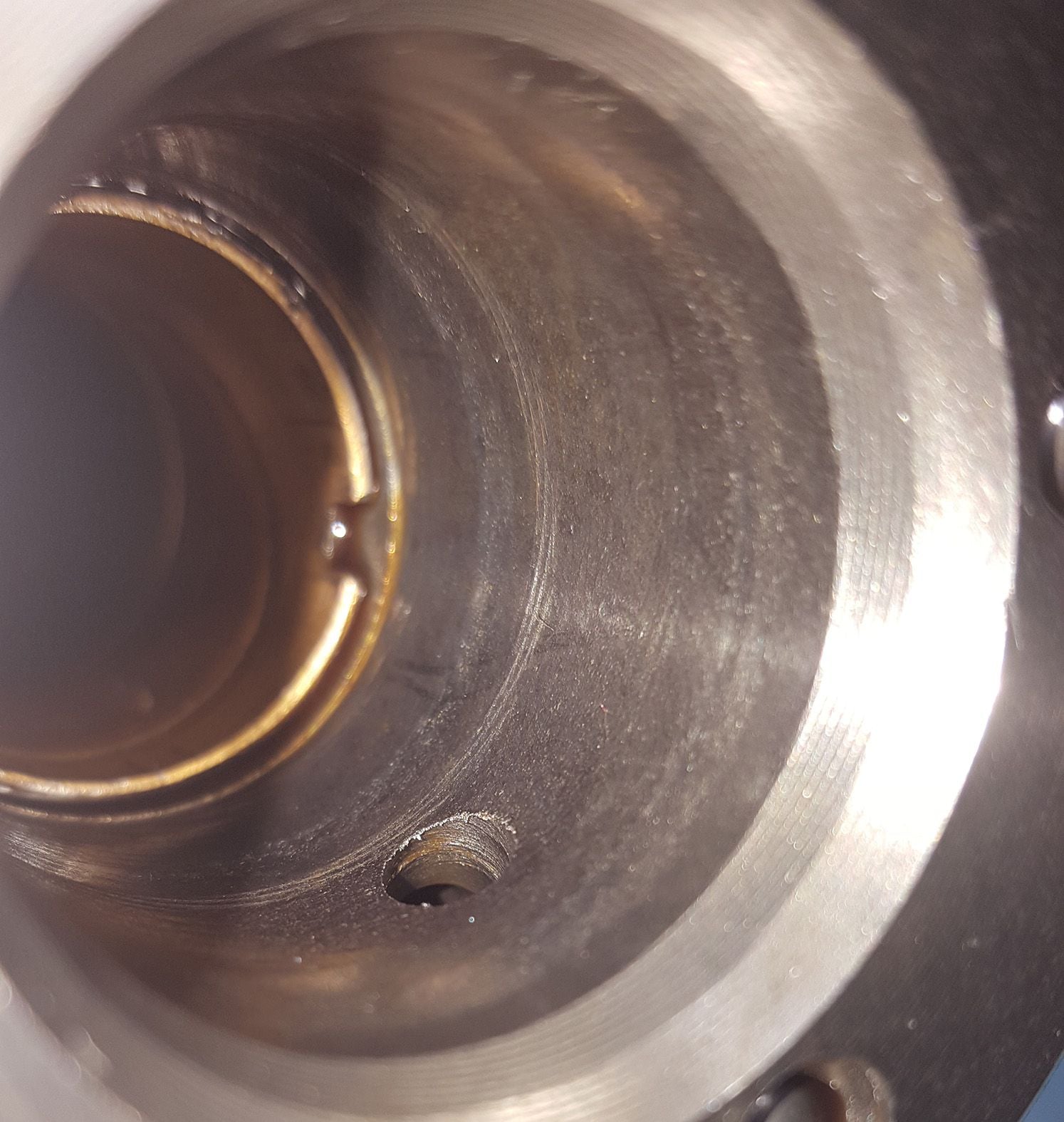

Long story, but the guy was replacing a blown engine, didn't tighten a connecting rod cap, sold it as a rocker arm noise. I bought it because he was selling it at a good price and I had an idea what was wrong with it. Fixed the engine and discovered a coolant leak after starting the engine. Discovered it coming from a hole in the transmission vent tube! found the person used some T fitting to connect it. connected everything where it needed to go and flushed it twice. Everything ran good for roughly a year and now this is where I am. Are you referring to the whiteish marks on the steels?

Long story, but the guy was replacing a blown engine, didn't tighten a connecting rod cap, sold it as a rocker arm noise. I bought it because he was selling it at a good price and I had an idea what was wrong with it. Fixed the engine and discovered a coolant leak after starting the engine. Discovered it coming from a hole in the transmission vent tube! found the person used some T fitting to connect it. connected everything where it needed to go and flushed it twice. Everything ran good for roughly a year and now this is where I am. Are you referring to the whiteish marks on the steels?

Trending Topics

#9

#10

I have a 3d printer and the means to design special tools to make this rebuild easier. When I'm done I will post a link to my thingiverse so anyone else can download and print them off. If there is interest, I can also make versions available on shapeways for those who don't have access to a 3d printer.

Last edited by MetalDrgn; 01-03-2018 at 12:59 PM.

#12

So now I'm working on cleaning and rebuilding everything and I've run into a problem.

I installed the new frictions and steels in the direct drum and now I don't have enough clearance. There's only about .030" and there's supposed to be 0.60"-.090". I checked the thicknesses with some digital calipers and the steels are roughly .02mm thicker, but the frictions are roughly .1mm thicker. That's each and all stacked together I get an extra 1mm thickness. These are the raybestos rht96-108. I checked them and they say 94 and on. Nothing I can find says it should change the clearance. I did find another video on youtube saying there are 2 different size steels for it as well and they were really close to that size. Maybe I need the thinner steels? Anyone have experience with this?

I installed the new frictions and steels in the direct drum and now I don't have enough clearance. There's only about .030" and there's supposed to be 0.60"-.090". I checked the thicknesses with some digital calipers and the steels are roughly .02mm thicker, but the frictions are roughly .1mm thicker. That's each and all stacked together I get an extra 1mm thickness. These are the raybestos rht96-108. I checked them and they say 94 and on. Nothing I can find says it should change the clearance. I did find another video on youtube saying there are 2 different size steels for it as well and they were really close to that size. Maybe I need the thinner steels? Anyone have experience with this?

Last edited by MetalDrgn; 02-18-2018 at 01:23 AM.