Current-gen trucks easier to repair in at least one respect

#1

Current-gen trucks easier to repair in at least one respect

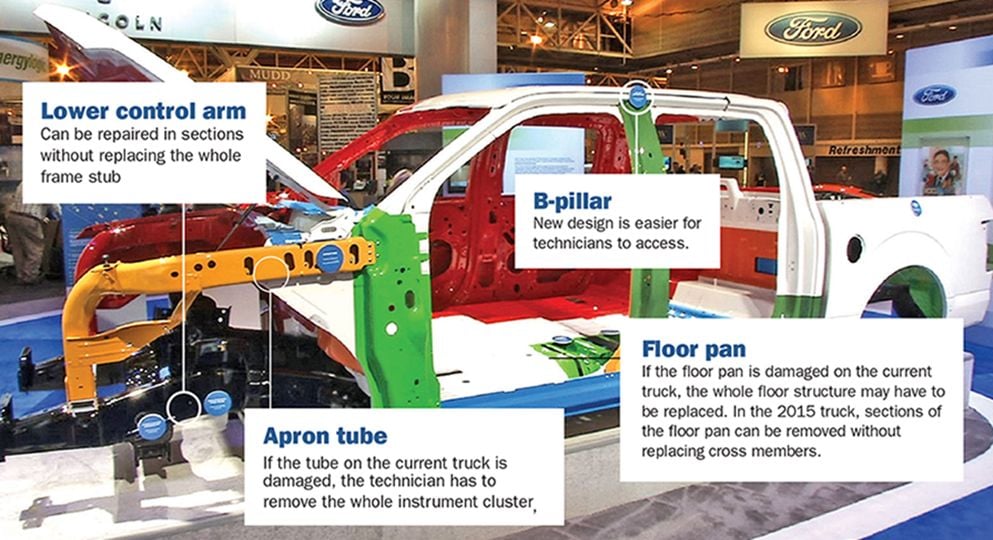

A lot of people made noise about the aluminum construction of the latest gen trucks, and higher repair costs was a key factor. But it turns out that Ford actually made it way easier to fix at least one area that was a total nightmare in the past. Apparently the entire dash had to come out to access the front apron tube on older trucks, but now it's a much simpler operation. Anyone ever went through this repair, on the new model or the old one? Check out the HP for more details.

#2

Interesting but the fact remains, major components are glued together, not welded. When the first F150s hit the streets with the aluminum, there was one Supercrew involved in a wreck that got posted here. The truck took heavy damage to the front right of it. The damage suffered from the wreck would have stopped at about mid front wheel as I recall. But the pic showed that the entire side of the truck fell off. The Supercrew front and rear doors suffered no damage except that they were part of the truck that literally fell off. There was no damage to the sheetmetal at all. Hard to believe Ford would turn out anything like it or any car maker. If you look close, it appears that Ford assembles the pillars with glue pads. It doesn't appear to be a direct glue. What would have happened if the rear passengers were not wearing a seat belt? I see this as a very bad thing. Love my Ford but this kind of assembly is not acceptable in my book. Yes, I understand this was a bad crash but the side of the truck coming off doesn't get it.

#4

That makes sense. The pic is pretty blurry on the mobile site but it looks like it was sliced. The edge doesn't seem to line up with body seams like it would be if the panel bond had failed. The panel bond in many cases is stronger than a weld, especially on aluminum. Many AL alloys don't weld very well, a 2024 for example will have to copper separate from the aluminum leaving it extremely weak in that area. The heat from welding also can damage the tempering in the area. I've seen two aluminum sheets were bonded together and pull tested. The metal tore before the bond failed.

#5

Interesting but the fact remains, major components are glued together, not welded. When the first F150s hit the streets with the aluminum, there was one Supercrew involved in a wreck that got posted here. The truck took heavy damage to the front right of it. The damage suffered from the wreck would have stopped at about mid front wheel as I recall. But the pic showed that the entire side of the truck fell off. The Supercrew front and rear doors suffered no damage except that they were part of the truck that literally fell off. There was no damage to the sheetmetal at all. Hard to believe Ford would turn out anything like it or any car maker. If you look close, it appears that Ford assembles the pillars with glue pads. It doesn't appear to be a direct glue. What would have happened if the rear passengers were not wearing a seat belt? I see this as a very bad thing. Love my Ford but this kind of assembly is not acceptable in my book. Yes, I understand this was a bad crash but the side of the truck coming off doesn't get it.

#6

Also consider, the outer skins on a truck are largely non-structural for the most part. The door skin does not make the door strong, it's nothing more than a thin piece of sheet metal to keep the rain out.

#7

I understand that the sheetmetal is not a structural component but the B Pillar between the front and rear door is structural. At one time I had a full story on this wreck and more pics but don't have a clue what I did with them or it could be on a different hard drive. I don't recall it hitting a wire and even if it did hit a wire as suggested, it would have turned the truck around, not cut it in half or rip one side off. I've been in a car that hit a guy wire and it certainly didn't cut into the car very far before the car swapped directions. There was more to this than that and a guy wire wouldn't have crushed the roof in.I also understand adhesives. For the pics I had it appears that Ford used adhesive pads, as in double sided pads to glue the parts on. While the adhesive might be good, the bond is subject to the overall strength of the pad materials. But in all fairness, I also haven't seen another truck come apart like this one. What would concern me though is after the adhesives are subject to many hot/cold cycles and UV light, just how long will they last before they fail. None of them are forever. Aluminum doesn't bother me in the least. Actually I applaud the use of it but it's like everything else, it's not what you do but how you do it.