SHOCKING NEWS How Twin Tube Shocks Work

When it comes to the control of your springs, the shock absorber is the only way to control it. Without the shock, the suspension would continuously bound and rebound all of the energy it has and your tires would never make proper contact with the road.

On this suspension tech, we’ll first take a look at Twin Tube Shocks and how they work. We’ll discuss other types in future articles.

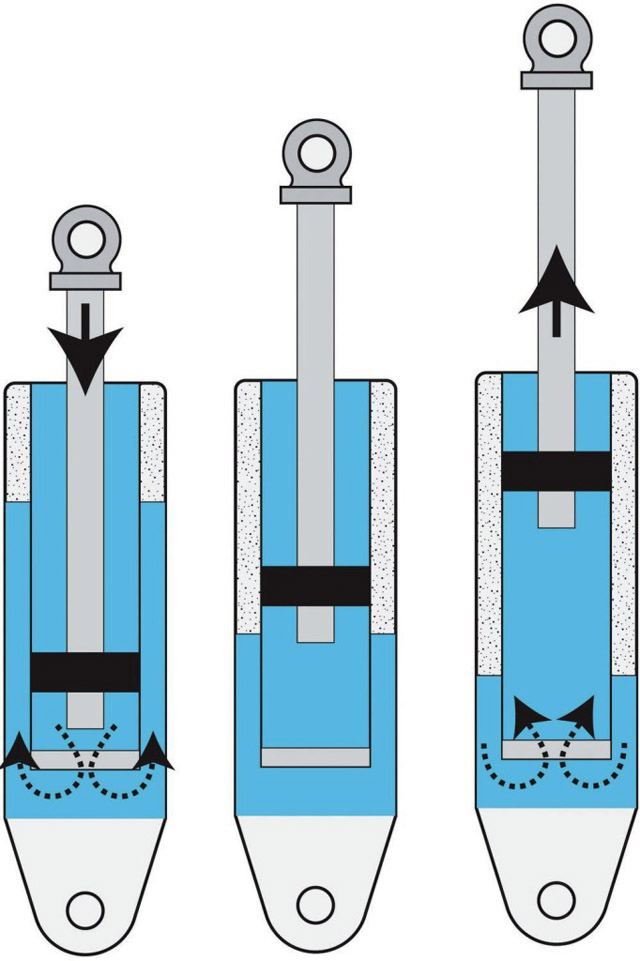

A Twin Tube Shock on the outside looks like a single piece on the body, but there are two tubes doing work inside of it. First, the tube you see on the outside is actually a reservoir for access fluid to bypass as the shock piston travels up and down. The tube on the inside is the one where the piston does its work.

The piston is designed with different orifices that are covered by metal shims that act as valves. In one direction, the shims keep certain orifices closed and allows oil to travel though those that are open. It’s vice-versa in the other direction. The orifices and valving in the piston are what gives the shock its profile in bound and rebound.

In between the two tubes is another valve that works to control oil between the two tubes and will also act as another way to control bound or rebound. How that piston and valve work and what they will control is determined by how the shock itself is designed and why you will see an arrow indicating which direction the shock is intended to work.

If the body of the shock is up towards the chassis, the body valve will be in control of bound while the piston will mostly control on rebound. If the body is pointed towards the axle (or ground), the body valve will control rebound while the piston will mostly control on bound.

There is also a low pressure gas in gas-charged twin tube shocks and typically nitrogen is used as the inert gas. However, both “basic” and charged shocks use gas (oxygen or otherwise) to control the fluid in the reservoir tube.

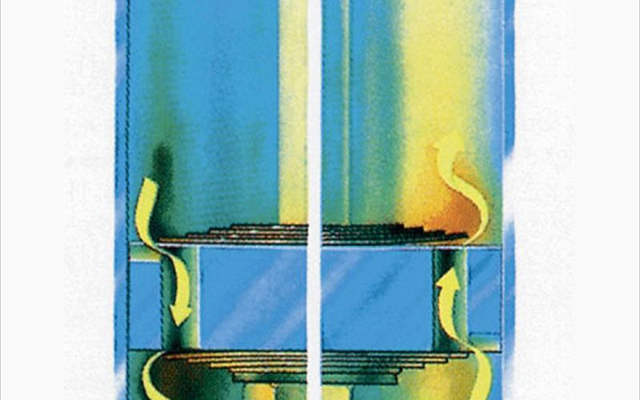

Using an inert gas is more consistent than normal air of a “basic” twin tube shock and helps prevent aeration which leads to shock fade. As the shock travels, it heats up and oil mixes with the gas, which lowers the damping rate as the viscosity of the oil will change with heat and aeration.

There are several advantages to using a twin tube shock. First, it’s an older technology and it is well known, tried, and proven, it’s cheaper.

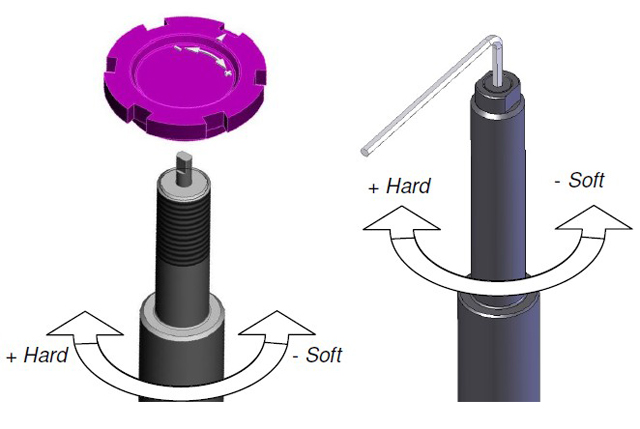

Second, for the aftermarket, it is a little easier to design for adjusting. You can have an adjuster on the shock rod to adjust the valving on the piston…

Then have an adjuster on the body to adjust the valve between the two tubes.

There are disadvantages as well. Aeration is a problem with twin tube shocks even when you use inert gas. They are also prone to damage having a drastic effect on dampening since the outer body is acting as a reservoir for the fluid.

In the next Shock article, we’ll look at Mono Tube Shocks and their advantages.